Benefits of rack inspection

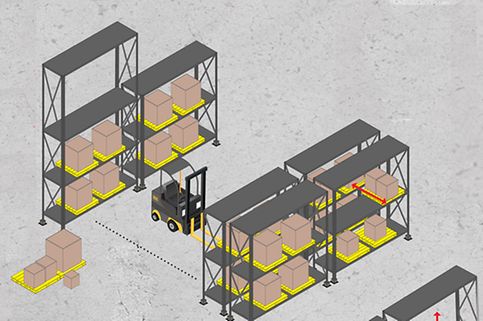

Racks are an integral part of the warehouse storage infrastructure. Equipped with racking systems that are well designed and maintained, managers can maximize the available space and optimize the warehouse for efficiency.

To ensure the warehouse works like a well-oiled machine, operating safely without any glitch with low or no accidents, proper inspection and maintenance is key in ensuring compliance with safety regulations such as the EN 15635, the European standard which SSI SCHAEFER adopts to define the inspection procedure for storage equipment/racking, and forestall mishaps. Rack inspection procedures are carried out by our own officially certified racking system inspectors. The results are documented within our Computerized Maintenance Management System (SSI SCHAEFER CMMS) App. All relevant information and photos are digitally stored and finally, all recorded data is summarized right away in an automatically generated PDF report.

There are risks when warehouses responsibles fail to put in place a system of inspection and maintenance, see “Risks of skipping rack inspection”, but what are the benefits of rack inspections?

Reliable supply chain. Warehouses play a vital role in the overall supply chain. Here, the products are stored, and the orders picked, packed, packaged and labelled for delivery. When done right, customer satisfaction goes up several notches.

Racks are the backbone of the warehouse. By enabling products to be stacked in an organized and efficient manner, they ensure goods in the warehouse are easily accessible for order fulfilment. When the racks function properly, they are an asset to the warehouse, ensuring smooth operation. Any mishap in the racking system can have adverse consequences which will ripple across the entire supply chain.

Good staff morale. Work occupies a good part of our waking hours and affect our health and wellbeing. Undesirable working conditions will invariably affect staff performance, increasing error rates and injuries. But the contrary is also true. With a good working environment, sound safety record and positive vibes, employees will be motivated to work harder and thus help the business to grow.

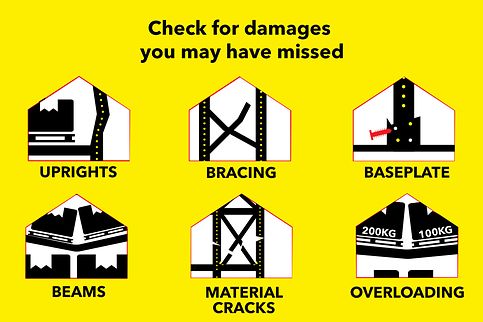

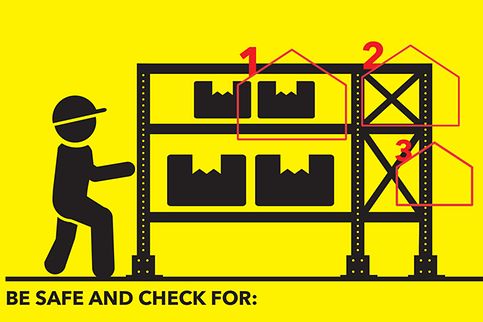

Longer shelf life. Storage racks are built to last. How long they last will depend on the environment in which they operate, and maintenance. Damaged upright frames, dented and bent beams or corroded components reduce their durability and longevity. By implementing a proper system of inspection and maintenance, the racks will provide more years of service.

Accidents are costly. The greatest risk of accidents is death, human lives cannot be replaced. Also property losses can be detrimental to businesses. Even relatively minor incidents can lead to loss of productivity, higher insurance premiums and possible fines for contravening safety regulations. Accidents involving racking systems are avoidable if preventive measures are adopted and the proper precautions are taken. By ensuring the warehouse is accident-free, the company can save a lot of money.

Insurance premium. In determining premiums for policyholders, insurance companies use risk assessment to calculate premium rates. Several factors are taken into account to gauge the risk that companies may file a claim against their policy. For warehouses, the critical risk factors often include fire, flood or security hazards, hazardous substances, employee safety, product damage and equipment failure. Warehouses which are considered low risk can expect lower insurance premiums.

Good brand image. People like to be associated with good brands. A strong brand name and image does miracles for the business, helping that potential customers remember the company.

Having a racking system which is in compliance with internationally accepted standards such as the European Standard EN 15635 as well as a good safety record – the number of accident free hours – hung on racks like a badge of honour, is of immeasurable value to the company, far more perhaps than having multiple advertisements.