12 Tips to Revolutionize Warehouse Management

How does technology drive cost reduction and productivity boost? Warehouse managers face the ongoing challenge of optimizing operations to increase productivity while reducing labor costs. Fortunately, advancements in technology have revolutionized the warehouse management industry, offering innovative solutions that can transform operations and yield remarkable results. This blog article will explore how warehouse managers can leverage technology to lower labor costs, boost operational productivity, and enhance efficiency.

1. Automated Inventory Management

Implementing an automated inventory management system is a foundational step toward reducing labor costs and enhancing productivity. By utilizing technologies such as barcode scanners, RFID tags, and inventory management software, warehouse managers can streamline inventory tracking and eliminate manual data entry. This automation significantly improves accuracy, reduces the time spent on manual counts, and enhances overall operational efficiency.

2. Warehouse Management Systems (WMS)

Adopting technology-driven warehouse management can revolutionize warehouse operations. Such software optimizes inventory placement, streamlines order fulfillment, and facilitates efficient picking and packing processes. A robust WMS software such as WAMAS integrates with other technologies, such as barcode scanners and RFID technology, allowing for seamless operations and real-time visibility. By optimizing workflow and reducing manual tasks, warehouse managers can achieve higher productivity levels with fewer labor resources.

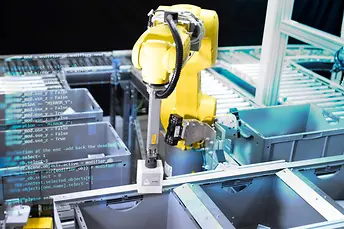

3. Robotics and Automation

Investing in robotics and automation technologies offers significant cost-saving opportunities for warehouse managers. Automated Guided Vehicles (AGVs) and robotic arms can handle repetitive tasks, such as picking, sorting, and stacking, with precision and speed. These technologies not only reduce labor costs but also improve accuracy, minimize errors, and increase throughput while ensuring an extremely rapid order processing time. Warehouse managers can reallocate their workforce to more value-added tasks, leading to a doubling of productivity and efficiency.

4. Predictive Analytics

Leveraging predictive analytics tools enables warehouse managers to make informed decisions based on data insights. By analyzing historical data, seasonal patterns, and customer trends, managers can optimize labor allocation, streamline workflows, and proactively plan for peak periods. This data-driven approach minimizes labor costs by ensuring the right amount of manpower is scheduled at the right time, thus eliminating labor inefficiencies and optimizing productivity.

5. Voice and Wearable Technologies

Implementing voice-directed picking systems and wearable technologies that are engineered to be portable, small, and ergonomic enough for operators to wear can significantly enhance productivity and efficiency. Voice-guided systems provide hands-free picking instructions to warehouse workers, reducing errors and improving speed. Wearable devices, such as smart glasses, scanners, and wristbands, can provide real-time updates and instructions, improving communication and reducing the need for manual paperwork. These technologies empower workers to perform tasks more efficiently and effectively, increasing productivity and reducing labor costs. Enhance productivity, reduce errors, and maximize efficiency with our game-changing voice and wearable technologies today.

6. Cloud Computing and Mobile Applications

Leveraging cloud computing and mobile applications offers warehouse managers the flexibility to access critical information anytime, anywhere. Cloud-based warehouse management systems enable real-time inventory tracking, order processing, and reporting. Mobile applications allow warehouse workers to update inventory status, record transactions, and communicate seamlessly, eliminating the need for paper-based processes and reducing time spent on administrative tasks. This digital transformation leads to improved efficiency, reduced labor costs, and enhanced overall productivity.

7. Automated Material Handling

Integrating automated material handling equipment, such as conveyor systems and Automated Storage and Retrieval Systems (ASRS), reduces the need for manual transportation and minimizes handling time. By automating these processes, warehouse managers can improve throughput, eliminate bottlenecks, and maximize resource utilization. This increased efficiency translates into cost savings as more work can be accomplished within shorter timeframes.

8. Machine Learning and Artificial Intelligence (AI)

Machine learning and AI technologies offer warehouse managers powerful tools to optimize operations and make data-driven decisions. These technologies can analyze vast amounts of data, identify patterns, and provide valuable insights for process improvement. AI-powered algorithms can optimize inventory placement, route planning, and labor allocation, resulting in cost savings and increased productivity. Additionally, AI-enabled predictive maintenance can anticipate equipment failures, reducing downtime and optimizing maintenance schedules.

9. Internet of Things (IoT) and Real-Time Monitoring

Harnessing the power of the Internet of Things (IoT) allows warehouse managers to monitor equipment performance, environmental conditions, and inventory levels in real-time. Wonder what are IoT sensors' data and their role in AI? IoT sensors and connected devices provide valuable data that can be used to identify patterns and trends in the warehouse and to track equipment performance as a measure of preventive maintenance. With the help of real-time monitoring, warehouse managers can proactively identify issues and take immediate corrective actions, minimizing disruptions and creating optimal environmental conditions for the operations to thrive.

10. Data Integration and Connectivity

Warehouse managers should prioritize data integration and connectivity to leverage the full potential of technology. Integrating various systems, such as WMS, inventory management, and transportation management systems, allows for seamless data exchange and real-time visibility. This integration eliminates manual data entry, reduces errors, and enhances decision-making capabilities. By having a comprehensive view of operations, managers can identify bottlenecks, optimize workflows, and improve overall efficiency. Thanks to this automation, managers can also resolve process bottlenecks to establish a smoother and more predictable flow, directly improving customer satisfaction as high order fulfillment rate is achieved.

11. Employee Training and Upskilling

While technology plays a pivotal role in lowering labor costs and increasing productivity, investing in employee training and upskilling is equally important. Warehouse managers should provide comprehensive training programs to ensure employees are proficient in utilizing technology and adapting to new processes. By empowering employees with the necessary skills and knowledge, managers can maximize the potential of technology, drive efficiency, and create a culture of continuous improvement within the warehouse

12. Continuous Monitoring and Optimization

Implementing technology is not a one-time fix; it requires continuous monitoring and optimization. Warehouse managers should regularly assess the performance of implemented technologies, identify areas for improvement, and explore emerging trends and advancements. By staying up to date with the latest technological developments, managers can continue to refine operations, lower labor costs, and maximize productivity.

In conclusion, as technology advances, it is crucial for warehouse managers to stay proactive, continuously evaluate their operations, and leverage the most relevant and effective technologies to drive success in today's competitive business landscape. Warehouse managers can harness the power of technology to lower labor costs, double productivity, and enhance overall efficiency. Automated inventory management, robust WMS, robotics, predictive analytics, voice and wearable technologies, cloud computing, IoT, machine learning, and data integration all contribute to significant cost savings and productivity gains. By embracing these advancements, warehouse managers can optimize workflows, minimize errors, streamline operations, and empower their workforce to focus on value-added tasks. Contact us now to embark on your technology-driven transformation!