Progress of Coop's New Distribution Center by SSI SCHAEFER

In October 2020, Coop, one of the leading food retailers in Sweden, and SSI SCHAEFER, the world’s leading provider of modular warehousing and logistics solutions, announced the starting point of their long-term collaboration. Once again SSI SCHAEFER met up with Mats Tornard, Project Manager of Strategic Supply Chain at Coop, to discuss and sum up the current success of the ongoing Automated Logistics Center project. At the end of 2021, the two companies shared information about the smooth collaboration, shared values in terms of quality and sustainability, and the status of the solution installation, which by that time had just started. Here's the update with the latest results.

Despite all the challenges and alterations, 2022 has been an eventful year for one of the largest automation projects in Europe. The global crisis, supply chain difficulties, and lack of steel failed to halt Coop’s solution realization. All major activities followed the schedule without disruption or delays. “We have had a very positive experience with all our partners so far. Despite the challenging 2022 year, both the building by the third party and the solution by SSI SCHAEFER are getting ready according to the realization plan,” shares Mats Tornard.

Constant Change is the New Stability

The past few years have been tricky in terms of planning for the future as behavioral habits shifted significantly. During the project realization, Coop updated input data, analyzed it, and concluded that the handover throughput volumes will reach 2027’s planned volumes. This means both the industry and the company growth have been outplaying the boldest expectations. While volume increase is undoubtedly great news, it comes with the consequences of solution revising and design changes.

During the solution’s realization stage we reviewed the data and found out that to handle the increased volumes in the future Coop will need more focus on palletizing and depalletizing. We are happy with the solution by SSI SCHAEFER as it allows extension at any point even in the middle of construction. In the dynamic world of today this is exactly what we need,

A Closer Look at What Has Been Done So Far

Sustainability and ergonomic work environments are at the forefront of the two companies shared values. Reaching high efficiency without compromising on important aspects is the core for Coop, especially during the design phase.

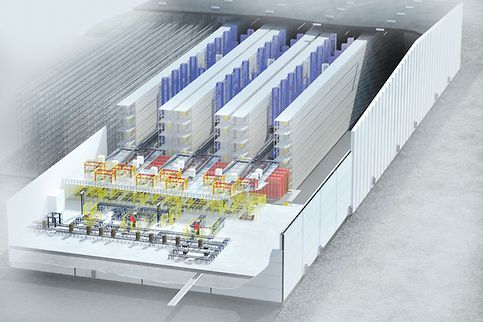

Goods will arrive by railroad straight to the warehouse to minimize CO2 footprint and to maintain an eco-friendly approach. The goods receiving zone is equipped with a pallet conveying system, which has already been completed and is now in the testing phase. High-Bay warehouses in both, chilled and ambient zones have been assembled and launched with pallet cranes that serve for storage and retrieval of goods for buffering.

When items are needed for restocking the main storage area, they arrive at the depalletizing station. Depalletizing, as well as mixed palletizing stations, are in progress due to an additional extension during realization, i.e. more robots. When the goods are split into individual cases, they are transported by a bin conveyor to a storage area. SSI SCHAEFER has just completed one of two parts of the bin conveying system.

The 3D-MATRIX Solution® by SSI SCHAEFER is intended to serve as a buffer for cases. The storage locations are operated by SSI Flexi shuttles, which are responsible for storage, loading, and retrieval. The buffer storage has also been extended and is currently a work in progress. The one part that is fully completed here is the installation of the lifts. After the cases are needed for the order, the SSI Flexi shuttles transport them to the palletizing station, where robotic equipment will take care of putting the orders together for shipping.

Assembled pallets are delivered to the buffer storage and are consolidated by the final customer or route. One of the shipping buffers is at the final stage and ready to be launched; the rest are in progress.

The Large Automation Project is Hard to Miss

2022 was a significant year for Coop and its partners. Coop was awarded the shared first place in the Logistics Establishment of the Year 2022! Coop's new goods terminal in Kjula, Eskilstuna impressed the judges with its major investment in train-bound grocery logistics and that the terminal will be highly automated. Coop's new warehouse is equipped with SSI SCHAEFER automated solutions and helps the retailer reach 95% of all the picking processes with automation. The main focus for the new internal logistics design was the ergonomic working environment and sustainability. Coop, SSI SCHAEFER, and other partners involved in the project visited the award ceremony to receive certificates and flowers.

"All the nominees presented fantastic projects. We were very happy to be among great and fair competition and were honored to receive the award," said Mats Tornard immediately after the award ceremony.

The project was also noticed for Coop’s sustainable initiatives towards both day-to-day work and the new warehouse. To reduce the CO2 footprint minimization, Coop is having solar panels installed on the roof. The panels are estimated to produce approximately one-third of the energy that the facility will need annually. Taking into account these and other company green activities, the judges awarded a decision in favor of Coop. Coop was named Sweden's most sustainable brand in Europe's largest brand survey on sustainability - “Sustainable Brand Index 2021.” Coop received a sustainability silver level certificate for the new site. This means that the new warehouse was recognized for its eco-friendly building construction and also healthy and ergonomic work environment for the employees.

Coop and SSI SCHAEFER are Creating More Jobs

Everyday thousands of packages are handled, formed, and sent to the end customer. Such an impressive building with a fully automated solution needs qualified people to monitor and control. To ensure the optimum operation of the system, SSI SCHAEFER is looking for new members for their team who are interested in career development and learning about automation and robotics. “Almost two years in the process, we are happy to share that the new logistics center is looking for employees and is ready to train and grow new specialists in the profession of the future. In total, we are looking for 79 technicians and professionals to support smooth and non-stop operations,” shares Mats Tornard.

SSI SCHAEFER and Coop are in need of qualified employees, and there is a huge competition to get them. Instead of compromising on quality, it was decided that it was time to be a part of the changing environment. That is why the companies initiated and joined the educational program together with Yrkeshögskolan SKY, one of the largest providers of Advanced Vocational Education in Sweden. To teach, mentor, and form a set of new specialists.

One of the biggest advantages of the educational program is that all the teachers have field experience. They work within the industry daily and can share the most recent news, trends, and techniques with the students. With the necessary drive, ambition, and success during the learning process, it is possible to land employment opportunities even before graduation.

The graduates can work as automation technicians in both inventory management and installation and service industrial robots, PLC technicians, robotics engineers, and maintenance technicians.

The information contained in the text is as of the end of November 2022. In the meantime, a lot has happened with the project, and there will be another update on progress soon.