Strong Partnership, Strong Logistics: SSI SCHAEFER Implements Highly Automated Warehouse for CERP

CERP and SSI SCHAEFER continue cooperation through new logistics center in Wissous, France.

Tailor-made solution for maximum efficiency and delivery quality in pharmaceutical logistics

Integrated concept with highly dynamic shuttle warehouse, piece picking robots, ergonomic work stations, the A-Frame automated picking system, and the smart logistics software WAMAS

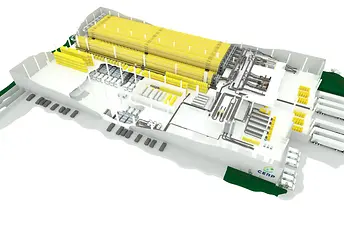

The new logistics center is planned as a greenfield project with a high degree of automation and will seamlessly integrate the processes of the existing site in Le Plessis-Robinson, France. Around 30,000 SKUs will be processed in Wissous on an area of 15,000 sqm. The goal: To increase throughput and handle larger volumes efficiently. By optimizing all processes, CERP will be able to respond even faster and more flexibly to growing customer and market demands.

The innovative solution includes storage and picking systems, storage bins, a conveying system, a pusher sorter for smooth shipping processing and intelligent software. The core of the new warehouse is a shuttle system with more than 90,000 storage locations – for maximum capacity and short access times. Two SSI Piece Picking robots, three Advanced Pick Stations one-level and a fully automated A-Frame system with over 2,900 product channels ensure fast and ergonomic picking according to the goods-to-person principle.

The entire facility is controlled by the WAMAS Warehouse Control System (WCS), which coordinates all processes in real time and thus noticeably increases efficiency, throughput and process reliability. The integrated WAMAS Control Center ensures maximum transparency as a central monitoring and information hub for all processes.

The concept is complemented by comprehensive services from SSI SCHAEFER: Technical support, targeted training, structured spare parts management and the WAMAS Maintenance Center, a computerized maintenance management system (CMMS) for the efficient administration of maintenance measures. This results in a future-proof, comprehensive package for pharmaceutical logistics.

“With the new system, we are consistently pursuing the strategic goal of expanding our position as an essential partner for supplying pharmacists with medicinal products,” states Jérôme Ibar, Technical Director at CERP. “The logistics center is perfectly tailored to our requirements and enables us to further automate and grow in the future.”

This forward-looking approach connects CERP and SSI SCHAEFER. Building on the trust gained, the new Wissous facility is expected to open in October 2026. The challenges are demanding: A tight schedule, the parallel coordination of various trades and commissioning scheduled for late 2027/early 2028. But both partners are convinced that this project will also be a complete success – thanks to the close cooperation of the well-coordinated team.