Once again, SSI Schaefer met up with Mats Tornard, Project Manager of Strategic Supply Chain at Coop, to discuss and sum up the current success of the ongoing Automated Logistics Centre project.

LUE LISÄÄOn the 1st of October 2022 the SSI SCHAEFER Group has appointed Michael Hillstrom as Managing Director of the SSI SCHAEFER Nordics (Danmark, Norge, Island, Sverige och Finland).

LUE LISÄÄ

SSI Schäfer osallistuu Tampereen Messu- ja Urheilukeskuksessa järjestettäville Logistiikka-messuille 14.–15.9.2022.

LUE LISÄÄ

Lauri Impiö, Head of Sales at SSI SCHÄFER Oy, will participate in intralogistics part of the LOGY Conference – “Update Your Business – How to succeed in the New Normal”.

LUE LISÄÄ

As a partner for sustainable logistics, SSI SCHAEFER has been active on the market for years. The sustainability strategy approved in fall 2021 will be implemented step by step. It will be presented together with the Sustainability Report 2021, which will be published in summer 2022. An example is the Vertical Farming solution in cooperation with Infarm, which involves supplying sustainably for an increasingly urbanized society. This was presented for six months at the Expo in Dubai and will now be exhibited at the LogiMAT 2022 trade fair in Stuttgart (Germany) in May.

LUE LISÄÄ![SSI_Expo 2020 Dubai_IMG_8696[2].jpg](/resource/image/895148/landscape_ratio3x2/320/0/ae832eba8486ce5e31db9f87b35ef1ed/2C46FFCBD30AD32F411404E131150B02/ssi-expo-2020-dubai-img-8696-2-jpg-dam-image-fi-29212-.jpg)

Neunkirchen/Siegerland / Dubai December 08, 2021 - The SSI SCHAEFER Group, a German family-owned company with a history spanning more than 80 years and a leading international provider of modular warehousing and logistics solutions, will be demonstrating what the sustainable supply of food to an urbanized society can look like at Expo 2020 in Dubai, which started on October 1. As an official partner of the German Pavilion Consortium, SSI SCHAEFER will present an innovative vertical farming solution developed in cooperation with Infarm, the world’s fastest growing vertical farming company, in the City of the Future section of CAMPUS GERMANY.

LUE LISÄÄ

In the age of e-commerce with maximum customer orientation and many services, order structures and throughput times in intralogistics have changed drastically. In order to transfer these multi-layered requirements into efficient logistics structures, companies need flexible logistics systems that work together in a perfect network, and these need to be controlled in transparent processes by powerful logistics software. SSI SCHAEFER covers this complex range and at LogiMAT 2022, it will present how its customers achieve a competitive advantage with future-proof intralogistics. Steffen Bersch, CEO of the SSI SCHAEFER Group: "As a leading solution provider in the market, we aim to create value for our customers with innovative products, outstanding project work and in a trusting partnership that leads them safely into the intralogistics future."

LUE LISÄÄ

SSI SCHÄFER toimitti vuonna 2020 varastointi- ja keräilyratkaisun pitkäaikaiselle kumppanilleen, Mitsubishi Logisnext Europe Oy:lle (aiemmin Rocla Oy), joka lukeutuu automaattitrukkiratkaisujen markkinajohtajiin. Toimitus piti sisällään lavahyllystöjärjestelmän sekä varastoautomaattiteknologiaa.

LUE LISÄÄ

SSI SCHAEFER is proud to have partnered with Coca-Cola Amatil to deliver their automated state-of-the-art facility featured in a series of recent corporate videos, released by Coca-Cola Amatil, one of the largest bottlers and distributors of beverages in the Asia Pacific region.

LUE LISÄÄ

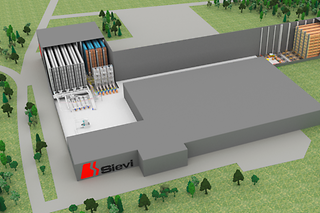

Back in 2017 NorgesGruppen ASA, one of the leading retail groups in Scandinavia, commissioned SSI SCHAEFER to build a new logistics center for its subsidiary company ASKO OSLOFJORD AS (ASKO).

Knut-Andreas Kran, CEO of ASKO OSLOFJORD AS, comments on the challenges the company experienced at the time: “ASKO anticipated a future capacity problem with only two possible solutions: either to extend the existing building or to relocate. We simply would not be able to keep up with the expected growth in the current location. We also did not want to just build a larger manual warehouse as we see that automation is an investment in the future.”

Snellmanin Kokkikartano Oy tunnetaan kotiruokareseptein valmistetuista valmisruuistaan. Kun Kokkikartano päätti rakentaa uuden logistiikkakeskuksen, se halusi kertatoimituksen sijaan löytää pitkäaikaisen kumppanin.

LUE LISÄÄ

Jututimme Coopin strategisten toimitusketjujen projektipäällikköä Mats Tornardia hankkeesta, sen nykytilasta sekä Coopin tulevaisuuden tavoitteista. Mats avasi hankintapäätöksen taustoja ja kertoi, miten ja miksi Coopilla päätettiin siirtyä täysin manuaalisesta varastosta yhteen maailman suurimmista automatisoiduista jakelukeskuksista.

LUE LISÄÄ

Tanskalainen Schou on Skandinavian suurin non-food-sektorin tukkuliike. Sen tuotekategorioita ovat kodin ja puutarhan tuotteet sekä vapaa-ajan tarvikkeet ja työkalut, ja asiakaskuntaan kuuluu muun muassa valtaosa pohjoismaisista vähittäismyyntiketjuista sekä ulkomaisia vähittäiskauppoja.

LUE LISÄÄ

Tarjoilemme asiakkaillemme vain tuoreimpia marjoja, ja niitä riittää kaikille!

LUE LISÄÄ

The Fraunhofer Institute for Material Flow and Logistics (IML) has successfully validated SSI SCHAEFER software in the validation of Warehouse Management System (WMS) solutions. With the help of the manufacturer-independent "WMS Online Selection", Fraunhofer IML supports companies in selecting the optimal suitable WMS and provider. The validation signet once again confirms the quality of SSI SCHAEFER software solutions.

LUE LISÄÄ

Ponsse, yksi maailman johtavista metsäkonevalmistajista, onnistui kasvattamaan kokoonpanolaitoksensa tuotannon tehokkuutta 50 prosenttia. Yhtenä kasvun mahdollistajana toimii SSI Schäferin toteuttama tuotannon sisälogistiikan älykäs automaatiojärjestelmä.

LUE LISÄÄ

Tallink on tehnyt kesäkuussa 2021 SSI SCHÄFERin kanssa sopimuksen seitsemän uuden SSI LOGIMAT® -varastoautomaatin toimituksesta.

LUE LISÄÄ

Flexible pouch sorter solution for e-commerce fulfillment

Changes in consumer and purchasing behavior are posing major challenges for many companies. Customers expect permanent availability of products and fast delivery to their doorstep. This increases the pressure on companies to meet the ever more complex customer requirements more efficiently. The need for automation with reliable technological and digital systems rises to be able to process orders quickly and ensure a high service level. Modern logistics systems such as the pouch sorter SSI Carrier by SSI SCHAEFER are able to meet these requirements. Thanks to the overhead conveying system, the global 3PL transport and logistics company DSV has sufficient capacity to deal with the exponential e-commerce growth of their customers and the massive seasonal order peaks - while handling products extremely gently.

The renowned US research and advisory company Gartner, Inc., lists SSI SCHAEFER with its software WAMAS® in the "Magic Quadrant for Warehouse Management Systems".

LUE LISÄÄ

Dr.Max Group, the biggest pharmaceutical chain in Eastern and Central Europe, commissioned SSI SCHAEFER to equip the new distribution center in Bucharest, Romania. The semi-automatic intralogistics solution to be implemented will supply B2B and B2C customers from only one warehouse and will reflect the strong growth as well as the future development plans of the company.

LUE LISÄÄ

SSI SCHAEFER becomes majority shareholder of SWAN: Partnership to strengthen SAP competencies while maintaining an independent presence in the market.

LUE LISÄÄ

Automaattiset SSI Cuby -sukkulavarastointijärjestelmät vakuuttavat kompaktilla rakenteellaan ja tehokkuudellaan ja tarjoavat samalla optimaalisen hinta-suorituskyky-suhteen

LUE LISÄÄ

Kuluttajapakattujen salaattien Suomen markkinajohtaja Fresh Servant on antanut SSI Schäferille tehtäväksi uuden logistiikkakeskuksen rakentamisen yhtiön Edsevön laitokselle. Uuden logistiikkakeskuksen lisäksi SSI Schäfer modernisoi yhden Fresh Servantin olemassa olevista logistiikkaratkaisuista.

LUE LISÄÄ

Mathem kasvaa rivakasti yhdessä pohjoismaisen elintarvikkeiden verkkokaupan kasvun myötä. Tukholman eteläpuolelle Larsbodaan perustettava uusi logistiikkakeskus on tärkeä osa jatkuvan laajentumisen prosessia. Yhtä tärkeässä roolissa on SSI Schäferin toimittama räätälöity automaatioratkaisu.

LUE LISÄÄ

Pohjois-Euroopan johtava turvajalkinevalmistaja Sievi investoi SSI Schäferin automaatioratkaisuun saadakseen kaiken hyödyn toimialan kasvusta

LUE LISÄÄ

In order to break logistics paradigms and modify their current supply chain, La Costeña, one of the biggest manufacturers of canned food in Mexico, worked together with SSI SCHAEFER to develop a major logistics solution that aims at increasing storage capacity, picking efficiency and dispatch production.

LUE LISÄÄ

The leading wholesaler and service provider Galexis AG ensures timely and consistent drug supply of all partners in the Swiss health sector. High-quality, modern intralogistics guarantees high customer satisfaction and successful market presence. In order to be prepared for future requirements, the distribution center in Lausanne-Ecublens is comprehensively expanded. The distribution center in Niederbipp has already been expanded.

LUE LISÄÄ

Dahl, the leading wholesaler and trading company in plumbing, pipes, groundwork, cooling, property and tools has selected SSI Schaefer as a supplier for its new central warehouse to cover the Swedish market.

LUE LISÄÄ

Apotea is Sweden's first full-scale and one of the fast-growing online pharmacy shipping around 700,000 packages a month. The company is well known for adopting the innovations presented on the market. In recent years, Apotea has built an environmentally friendly logistics center and installed an automated system from SSI Schaefer to keep up with rapid growth.

LUE LISÄÄ

Pohjoismaiden johtava hiusten- ja kauneudenhoidon asiantuntija, Ruotsissa pääkonttoriaan pitävä Lyko luottaa jälleen SSI Schäferin asiantuntemukseen, kun aiemmin toteutettua automatisoitua varastoratkaisua laajennetaan.

LUE LISÄÄ

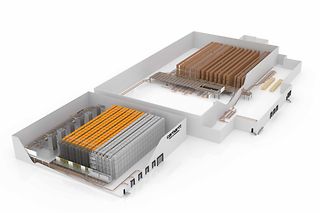

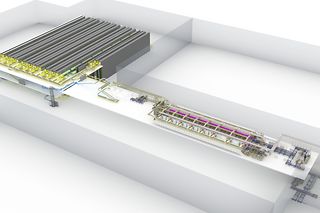

Ruotsin eräs johtava elintarvikkeiden vähittäiskauppias Coop on valinnut SSI SCHÄFERin sisälogistiikan pääurakoitsijaksi toteuttamaan huippumodernin, energiatehokkaan ja pitkälle automatisoidun logistiikkaratkaisun uuteen 77000 neliömetrin Eskilstunan jakelukeskukseensa.

LUE LISÄÄ

The leading wholesaler and service provider Galexis AG ensures timely and consistent drug supply of all partners in the Swiss health sector. High-quality, modern intralogistics guarantees high customer satisfaction and successful market presence. In order to be prepared for future requirements, the distribution center in Lausanne-Ecublens is comprehensively expanded. The distribution center in Niederbipp has already been expanded.

LUE LISÄÄSHOP APOTHEKE EUROPE, one of Continental Europe’s leading online pharmacies, commissioned SSI SCHÄFER to equip their new logistics center in Sevenum, the Netherlands. The highly automated solution will increase the possible shipping volume to more than 35 million parcels per year and has been designed for zero-error tolerance and 24/7 operations. The investment is in the medium double-digit million range.

LUE LISÄÄ

Rackel completes the C-Suite Management Team for the SSI SCHÄFER Group

The Advisory Board of the SSI SCHÄFER Group has appointed Mr Harald Rackel as COO of the SSI SCHÄFER Group. Mr Rackel will start his position at SSI SCHÄFER on 1 October 2020.

The EDEKA Group Nordbayern-Sachsen-Thüringen expands and automates their regional warehouse in Gochsheim, Germany with SSI SCHÄFER.

LUE LISÄÄ

Koenig & Bauer (AT) GmbH takes a step further towards automation with SSI SCHÄFER and modernizes the Maria Enzersdorf location. The printing press manufacturer commissioned SSI SCHÄFER to supply and install a semi-automated solution with 13 SSI LOGIMAT Vertical Lift Modules for small parts vertical and efficient item picking.

LUE LISÄÄ

SSI SCHÄFER launches a virtual stand giving current clients and interested companies a glimpse of software technology and equipment solutions. Since LogiMAT trade fair was canceled, SSI SCHÄFER is highlighting products and solutions slated to demonstrate the latest innovation in products and services. Our team of experts demonstrate key technologies and offer personal dialogue with our specialists. Individual consulting and information are part of the virtual experience – just like the exhibition was intended.

LUE LISÄÄ

One of the worldwide leading solution providers of modular warehousing and logistics solutions, SSI SCHAEFER, and the solution provider of automatic picking and digital applications, BD Rowa, will continue to cooperate. The two companies extended the corresponding contract by five more years. The aim of the cooperation is to provide customers in the healthcare sector with an overall solution to prepare them for future processes, such as e-prescriptions or establishing Hub & Spoke models.

LUE LISÄÄ

In the light of the rapid spread of the COVID-19 (coronavirus), the SSI SCHAEFER Group cancels the participation in the intralogistics trade fair LogiMAT. The health of employees and customers is more important. SSI SCHAEFER will participate with customers and interested fair visitors by offering a virtual fair stand. This digital presentation will include key technologies as well as the option for a personal consultation with experts.

LUE LISÄÄ

SSI SCHÄFER wins internationally experienced manager as CEO

The positions of the Group's Management Board have now been effectively filled.

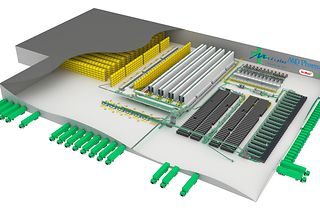

MISUMI, a global manufacturer and leading provider of mechanical components and indirect materials for special machine construction and assembly automation, has commissioned SSI SCHAEFER to implement a new logistics center in Frankfurt/Main. Until the beginning of 2020, the distribution center with a capacity for 450,000 items on more than 10,000 m2 of storage area will be built in several stages. Core elements of the system are an automated shuttle warehouse, a four-storied rack system, ergonomic work stations connected via a conveying system and the logistics software WAMAS®.

LUE LISÄÄ

The Maintenance 4.0 for Intralogistics concept for condition monitoring and semi-automatic maintenance was developed by SSI SCHAEFER in partnership with Schaeffler. Now, the solution is among the winners of LOGISTRA magazine’s “LOGISTRA Best Practice: 2018 Innovations” Readers’ Choice Awards. The accolade underscores the inventive and future-proof design.

LUE LISÄÄ

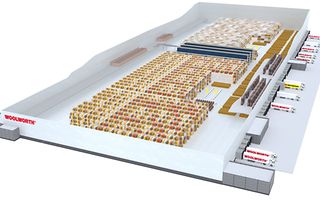

Only several kilometers away from the previous location in the eastern Ruhr area in Germany, the ERL Euro Retail Logistics GmbH builds a new central warehouse on behalf of the Woolworth GmbH. SSI SCHÄFER was awarded the contract for the implementation of intralogistics. A balanced mix of manual and automated processes characterizes the solution to be implemented.

LUE LISÄÄ

Every two years, Bosch honors the best of their suppliers from around the world with the “Bosch Global Supplier Award”. This year, SSI SCHÄFER received the award in the category "Purchasing of indirect materials", in the field of plastic injection moulding containers. Bosch rewards outstanding performance in the manufacture and supply of products or services – very important are quality, costs, innovation, and logistics. From its roughly 43,000 suppliers, Bosch awarded 47 suppliers from 15 countries.

LUE LISÄÄThe strong growth and global orientation of SSI SCHÄFER result in a worldwide investment boost for the company: New employees, prestigious buildings, and state-of-the-art production facilities – the intralogistics specialist has a lot going on around the globe, and developments are continuously being reported. Currently, one of the greatest milestones is the construction of new buildings at the existing locations Giebelstadt and Friesach, which will not only create more space for new employees, but will also support a modern corporate culture. The very popular sector of Customer Services & Support in Graz has also moved into a new space, given that its number of employees more than doubled in a short time.

LUE LISÄÄ

MISUMI, a global manufacturer and leading provider of mechanical components and indirect materials for special machine construction and assembly automation, has commissioned SSI SCHÄFER to implement a new logistics center in Frankfurt/Main. Until the beginning of 2020, the distribution center with a capacity for 450,000 items on more than 10,000 m2 of storage area will be built in several stages. Core elements of the system are an automated shuttle warehouse, a four-storied rack system, ergonomic work stations connected via a conveying system and the logistics software WAMAS®.

LUE LISÄÄ

Apotea, The largest online pharmacy in Sweden has grown rapidly since they started in 2012. Last year the company distributed 6 million packages and also moved in to a new built climate smart logistic center. Much of the order processing is done manually but now Apotea takes a step forward and will get an automated solution.

LUE LISÄÄ

SSI SCHAEFER Welcomes Formula 2 Driver Mick Schumacher as Brand Ambassador

LUE LISÄÄ

As general contractor for intralogistics, SSI SCHAEFER provides a new logistics building for Work in Progress Textilhandels GmbH (Carhartt WIP), including a Cuby shuttle system, a compact bin and carton conveying system as well as picking locations with sequencing tower. Furthermore, the existing automated shipping buffer will be extended and connected to the new system technology.

LUE LISÄÄ

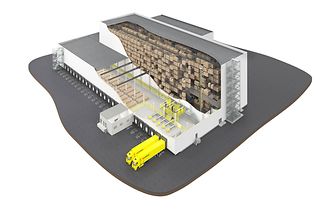

The drugstore chain Rossmann commissioned SSI SCHAEFER to automate their central warehouse in their Polish subsidiary in Łódź. In addition to installing a custom-fit pallet and bin conveying system, implementing 84 ergonomic work station systems and the logistics software WAMAS®, SSI SCHAEFER will equip a 10-aisle miniload with more than 100,000 bin storage locations operated by SCHAEFER Miniload Cranes (SMC).

LUE LISÄÄ