SSI SCHÄFER og Moffett Automation inngår partnerskap for å levere avanserte 4D-pallet shuttle-systemer til høyytelseslagre

Et strategisk samarbeid mellom intralogistikkeksperten SSI SCHÄFER og Moffett Automation, en spesialist innen automatiserte pallagerløsninger.

Partnerskapet kombinerer SSI SCHÄFERs globale systemintegrasjonskompetanse med Moffett Automations høy-densitetsløsninger for pallagring og deres avanserte 4D-shuttleteknologi.

Resultatet er integrerte systemer som leverer maksimal effektivitet, fleksibilitet og kostnadseffektivitet i et bredt spekter av lagermiljøer.

SSI SCHÄFER, en ledende global leverandør av intralogistikkløsninger, og Moffett Automation, leverandør av pallagringssystemer basert på free-roaming shuttleteknologi, går nå sammen for å forme fremtidens lagerautomatisering. Partnerskapet gjør det enklere for kundene å implementere moderne, skalerbare pallet shuttle-systemer som oppfyller høye krav til både ytelse og arealeffektivitet.

”Våre selskaper deler de samme verdiene. Begge er familieeide, har flere tiårs erfaring og et sterkt driv for å videreutvikle logistikkbransjen”, sier Mauro Lunardelli, Head of Business Unit Logistics Solutions i SSI SCHÄFER. ”For oss begge er kundefokus og pålitelighet helt avgjørende.”

”For Moffett Automation er dette partnerskapet fullt ut i tråd med vår misjon om kontinuerlig innovasjon og levering av intelligente, arealeffektive pallagringssystemer som er praktiske å implementere i reelle lageroperasjoner”, sier Sam Moffett, grunnlegger og Managing Director i Moffett Automation. ”Ved å kombinere vår 4D-shuttleteknologi og egenutviklede programvare med SSI SCHÄFERs WAMAS warehouse management system (WMS), globale rekkevidde og systemintegrasjonskompetanse, skaper vi svært innovative løsninger som gir kundene trygghet til å automatisere – selv i de mest komplekse eller arealbegrensede byggene.”

SSI SCHÄFER og Moffett Automation har inngående forståelse for utfordringene mange virksomheter står overfor. Mange trenger ikke bare skalerbare løsninger, men må også håndtere bygningsmessige begrensninger som lav takhøyde eller komplekse lagerutforminger. Slike forhold forsinker ofte overgangen til automatisering.

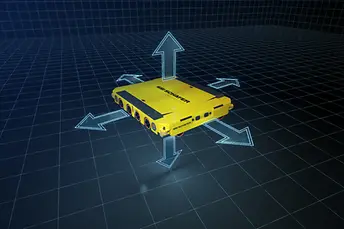

Det er her intelligente 4D-shuttler og integrerte pallagringssystemer kommer til sin rett. De kompakte shuttlene kan bevege seg selvstendig langs reolganger, tverrganger og mellom ulike nivåer, velge den mest effektive ruten gjennom systemet og levere høy ytelse – også i fryselager.

Et partnerskap som løfter lagerautomatiseringen til neste nivå

Den kompakte designen og multidireksjonale bevegelsen gjør at shuttlene utnytter tilgjengelig areal svært effektivt, samtidig som løsningene forblir kostnadseffektive i lagre med varierende throughput-profiler. Avansert styringsprogramvare muliggjør korte tilgangstider, høy kapasitet og jevn vareflyt. Systemet kan integreres med eksisterende WMS-løsninger, konfigureres fleksibelt og bygges ut trinnvis. Dermed blir automatisering mulig også der det tidligere har blitt vurdert som for komplekst eller for kostbart.

”4D-shuttleteknologi er en reell game changer, særlig i en tid der fleksibilitet og effektivitet er avgjørende”, sier Markus Schellinger, Head of Market Sector Production Logistics i SSI SCHÄFER. ”Ved å utvide porteføljen vår kan vi tilby enda bedre skalerbarhet og støtte kundene i deres vekst. Samtidig får de fordelene av enkel integrasjon mot eksisterende WMS-systemer og AI-støttet ruteplanlegging.”

De første felles prosjektene mellom SSI SCHÄFER og Moffett Automation er allerede under oppstart. Begge parter er overbevist om at dette kun er starten på et langsiktig samarbeid som vil sette tydelige spor i utviklingen av lager- og intralogistikkløsninger.

Med SSI Pallet Roaming Shuttle tilbyr SSI SCHAEFER en skalerbar shuttleløsning for inngang til lagerautomatisering.