SSI SCHAEFER and Coop Receive Multiple Awards for Sustainable and Efficient Intralogistics Solution

Best of Industry Award for SSI SCHAEFER in the category “Sustainability”

reta Award in the category “Supply Chain Excellence” for Coop – SSI SCHAEFER recognised as “Top Supplier Retail”

Recognition of one of the most modern and sustainable logistics solutions in the European food retail sector

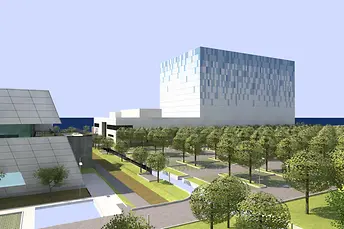

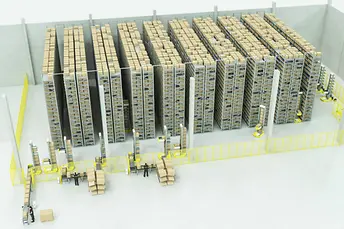

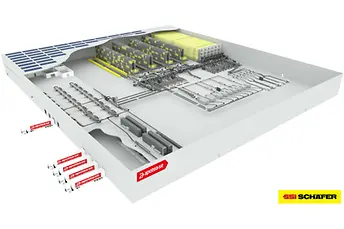

The distribution center in Eskilstuna, Sweden, realised by SSI SCHAEFER as general contractor for Coop, has received significant recognition twice and was honoured with two prestigious industry awards: the Best of Industry Award and the reta Award. The highly automated facility covers the entire material flow from goods receiving to shipping and approximately 95% of picking processes.

The Best of Industry Award honours outstanding industrial projects each year that demonstrate measurable efficiency improvements, technological innovation, and sustainable operating models. In this year’s reader vote, approximately 25,000 votes were cast across 19 categories. In the ‘Sustainability’ category, SSI SCHAEFER impressed with the highly automated distribution centre for Coop. At Coop, the focus on sustainability is particularly evident: consolidating ambient and chilled operations into a single central warehouse reduces transportation routes and CO₂ emissions. Thanks to Sweden’s second-largest photovoltaic system, the distribution centre generates approximately one-third of its own electricity. The remaining power is sourced from renewable energy, meaning the entire facility operates on green electricity, making a significant contribution to resource-efficient and climate-friendly logistics.

The reta Award presented by the EHI Retail Institute is among the most important distinctions for technological excellence in the retail sector. It recognizes projects that measurably optimise supply chains and successfully integrate digital process innovations into day-to-day operations. Coop received the reta Award in the category ‘Supply Chain Excellence’, which in turn recognises SSI SCHAEFER as a ‘Top Supplier Retail’. This distinction acknowledges that the jointly implemented logistics project enables a particularly high‑performing and sustainable supply chain, thanks to its high degree of automation, stable material flows, and the significant reduction in transport volumes.

“The two awards demonstrate the difference that innovative, intelligently integrated intralogistics solutions can make for entire supply chains today. Together with Coop, we have implemented a facility that combines sustainability, scalability, and maximum process stability, serving as a model for the future of the food retail industry,” says Peter Lambrecht, Global Head of Sales Logistics Solutions, SSI SCHAEFER.

F. l. t. r.:

Patrik Danielsson – Head of Warehouse Operations at Coop Logistik AB

Mattias Hjerpe Persson – Head of Operations Control at Coop Logistik AB

Andreas Hümmer – GC Project Manager Realization at SSI SCHAEFER

Ralf Bleifuß – Vice President Global Strategic Projects at SSI SCHAEFER

© Sebastian Human/VCG

F. l. t. r.:

Ralf Bleifuß - Vice President Global Strategic Projects at SSI SCHAEFER

Patrik Danielsson - Head of Warehouse Operations at Coop Logistik AB

Örjan Grandin - CEO at Coop Logistik AB