Efficiency Meets Maximum Warehouse Capacity: ELMAG Relies on an Integrated Logistics Solution by SSI SCHAEFER

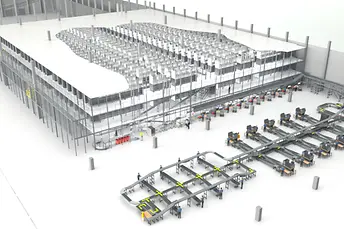

SSI SCHAEFER is setting up a new warehouse in Tumeltsham near Ried im Innkreis, Austria for the tool and machine wholesaler ELMAG

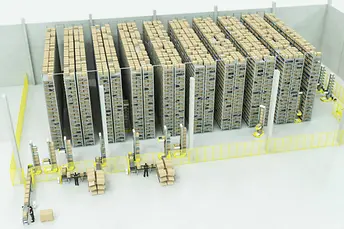

Semi-automated solution for space-saving storage and powerful picking capabilities

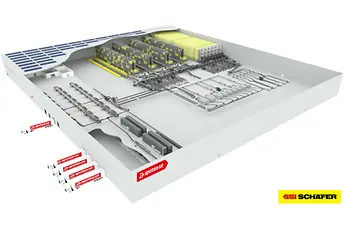

Overall concept consists of mobile pallet racking, cantilever racking and SSI LOGIMAT ® lift modules

Powered by Quality – under this motto, ELMAG Entwicklungs- und Handels GmbH has been marketing high-quality machines and tools for commerce, industry, and the trades, as well as for quality-conscious private users, for over 40 years. The Austrian family-run company supplies specialist retailers in around 25 countries with compressed-air technology, welding technology, metalworking machinery, stone-cutting technology, workshop equipment and generators. To manage this wide range of products and ensure high quality and delivery reliability in the future, a new logistics center is being built at the company site in Tumeltsham.

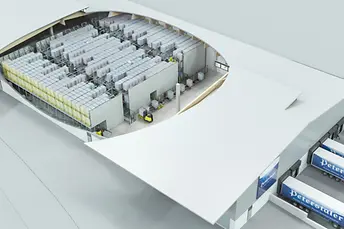

"Although the building planning had already been completed, SSI SCHAEFER was able to integrate a mobile racking system for ELMAG. The alternative approach created up to 90% more storage capacity in the same space along with significantly simpler storage retrieval. This efficiency convinced ELMAG," explains Alfred Spicker, Head of Dynamic Systems at SSI SCHAEFER.

For the new logistics center, SSI SCHAEFER created a space-saving, semi-automated solution, which is able to store both large and heavy goods as well as small parts – and ensures the smooth flow of goods. Two heavy-duty mobile racking systems of robust steel construction are ideal for pallets with loads of up to 500 kg and enable maximum flexibility for special load carriers, thanks to grating supports on selected storage positions. The individually configured system delivers picking functions and meets the highest safety requirements with components such as radio remote control, pre-warnings, two-way access monitoring and automatic stacker release.

Particularly long or bulky goods can also be accommodated in the area around the mobile racking systems with additional cantilever racking systems. Three SSI LOGIMAT lift modules are also used to create even more capacity and throughput. They combine small-parts storage and goods-to-person picking in one system and increase picking performance by up to 20%. By using the full room height, each lift provides space for at least 63 trays, each with a load capacity of 400 kg. Confirmation light barriers, optical position displays and a touch display ensure intuitive operation and ergonomic working.

The new logistics solution offers ELMAG numerous benefits: Unlike in narrow-aisle warehouses, pallets can be supplied directly using reach trucks without any intermediate transfer. Manual picking is also significantly more efficient, flexible, and safer in the mobile racking system. At the same time, investment costs are reduced, the best use is made of the available space and the modular design enables racks and warehouse lifts to be expanded at any time. Software integration is also simple.

"The new system also gives us flexibility for future growth," stated Christian Weiss from ELMAG. "In addition to comprehensive problem solving and on-site proximity, the competent overall consultation on all topics was the reason why we chose SSI SCHAEFER as our partner."

Project start is planned for the end of 2025, and commissioning should take place by the end of spring 2026. SSI SCHAEFER will handle the entire project – from planning to go-live and beyond.