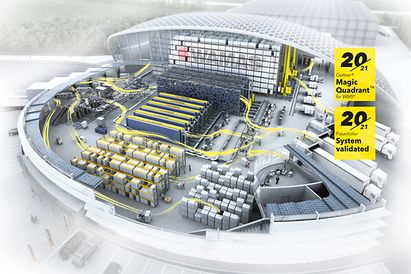

Work in Progress: How is Coop’s new automated DC by SSI Schaefer doing?

In October 2020, Coop, one of the leading food retailers in Sweden, and SSI Schaefer, the world’s leading provider of modular warehousing and logistics solutions, announced the starting point of their long-term collaboration.

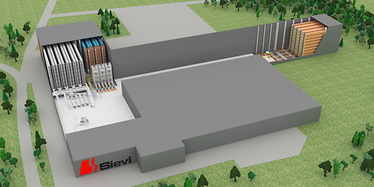

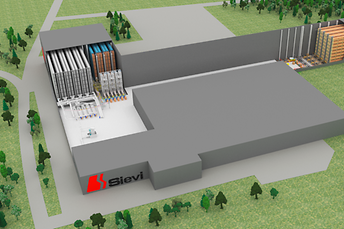

Once again SSI Schaefer met up with Mats Tornard, Project Manager of Strategic Supply Chain at Coop, to discuss and sum up the current success of the ongoing Automated Logistics Centre project. At the end of 2021, we published an article on both companies’ smooth collaboration, shared values in terms of quality and sustainability and the status of the solution installation which by that time had just started. Now it is time to update you with the latest results we have achieved together so far. Despite all the challenges and alterations, 2022 has been an eventful year for the largest automation project in Europe. The global crisis, supply chain difficulties and lack of steel failed to hold back Coop’s solution realization. If we take a look at the initial plan, all major activities follow the schedule with no disruption or delays.

“We have had a very positive experience with all our partners so far. Despite the challenging year 2022, both the building by the third party and the solution by SSI Schaefer are getting ready according to the realization plan”, shares Mats Tornard.

Constant change is the new stability

The past few years have been tricky in terms of planning for the future as behavioral habits shifted significantly. During the project realization Coop updated input data, analyzed it and concluded that the handover date volumes will reach 2027’s planned volumes. This means both the industry’s and the company’s growth have been outplaying the boldest expectations. While volume increase is undoubtedly great news, it comes with the consequences of solution revising and design changes.

“During the solution’s realization stage we reviewed the data and found out that to handle the increased volumes in the future Coop will need more focus on palletizing and depalletizing. We are happy with the solution by SSI Schaefer as it allows extension at any point even in the middle of construction. In the dynamic world of today this is exactly what we need”, continues Mats.

What has been done so far: installation of the system

When we talk about shared values, sustainability and ergonomic work environments come to mind first. These were the core points for Coop at the solution design stage: to reach high efficiency without compromising on the important aspects.

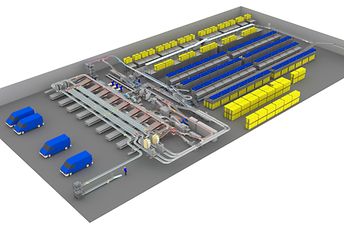

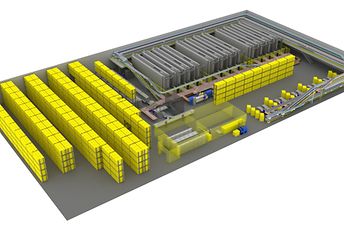

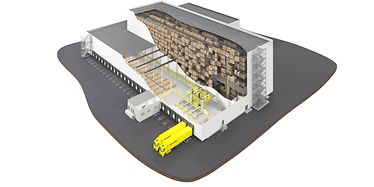

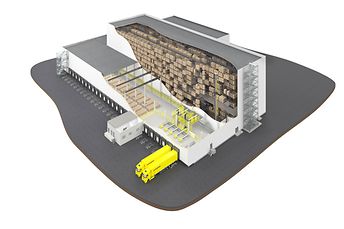

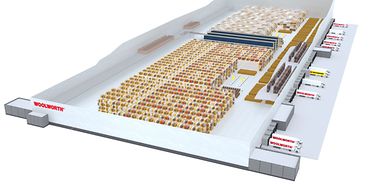

Goods will arrive by railroad straight to the warehouse to minimize CO2 footprint and maintain an eco-friendly approach. The goods receiving zone is equipped with the conveying system for pallets, which has already been completed and is now on a test run. High-Bay warehouses in both, chilled and ambient zones have been assembled and launched together with the pallet cranes that serve for storage and retrieval of goods for buffering.

When the items are needed for restocking the main storage area, they arrive at the depalletizing station. Depalletizing, as well as mixed palletizing stations, are in progress due to additional solution extension during realization, i.e. more robots. When the goods are split into individual cases, they are transported by a bin conveyor to a storage area. SSI Schaefer has just completed one of two parts of the bin conveying system.

The 3D-MATRIX Solution® by SSI Schaefer is intended to serve as a buffer for cases. The storage locations are operated by SSI Flexi shuttles, which are responsible for storage, loading and retrieval. The buffer storage has also been extended and is currently a work in progress. The one part that is fully completed here is the installation of the lifts. After the cases are needed for the order, the SSI Flexi shuttles will transport them to the palletizing station where robotized equipment will take care of putting the orders together for shipping.

Assembled pallets are delivered to the buffer storage and are consolidated by the final customer or route. One of the shipping buffers is at the final stage and is ready to be launched, the rest of them are in progress.

The largest automation project in Europe is hard to miss

2022 is a significant year for Coop and its partners. Coop was awarded the shared first place of the Logistics Establishment of the Year 2022! Coop's new goods terminal in Kjula, Eskilstuna impressed the jury with its major investment in train-bound grocery logistics and that the terminal will be highly automated.

Coop's new warehouse is equipped with SSI Schaefer’s automated solutions and helps the retailer reach 95% of all the picking processes completed with automation. The main focus for the new internal logistics design was ergonomic working environment and sustainability. Coop, SSI Schaefer and other partners involved in the project visited the award ceremony to receive diplomas and flowers.

"All the nominees presented fantastic projects. We were very happy to be among great and fair competition and were honored to receive the award," said Mats Tornard immediately after the award ceremony.

The project was also noticed for Coop’s sustainable initiatives towards both, day-to-day work and the new warehouse. To add up to CO2 footprint minimization, Coop will also have solar cells on the roof. The panels are estimated to produce approximately one third of the energy that the plant will need annually. Taking into account these and other company’s green activities, the jury made a decision in favor of Coop. Coop was named Sweden's most sustainable brand in Europe's largest brand survey on sustainability - “Sustainable Brand Index 2021”. Coop received a sustainability certificate for the new site with the silver level. This means that the new warehouse was recognized for its eco-friendly building construction and also healthy and ergonomic work environment for the employees.

Coop and SSI Schaefer are creating more jobs

Every day thousands of packages are handled, formed and sent to the end customer. Such an impressive building with a fully automated solution needs qualified people to monitor and control. To ensure the optimum operation of the system, SSI Schaefer is looking for new members for their team who are interested in career development and learning about automation and robotics.

“Almost two years in the process, we are happy to share that the new logistics center is looking for employees and is ready to train and grow new specialists in the profession of the future. In total, we are looking for 79 technicians and professionals to support smooth and non-stop operations”, shares Mats.

SSI Schaefer and Coop are in need of qualified employees and there is a huge competition to get them. Instead of compromising on quality, it was decided that it is time to be a part of the changing environment. That is why the companies initiated and joined the educational program together with Yrkeshögskolan SKY, one of the largest providers of Advanced Vocational Educations in Sweden. To teach, mentor and form a set of new specialists.

One of the biggest advantages of the educational program is that all the teachers have field experience. They work within the industry on the daily basis and are able to share the most recent news, trends and techniques with the students. With the necessary drive, ambition and success during the learning process, it is possible to land employment opportunities even before graduation.

The graduates can work as Automation Technicians in both Inventory Management and installation and service industrial robots, PLC Technicians, Robotics engineers, and Maintenance technicians.

To apply for the program, a student needs a diploma from an Upper Secondary School in Sweden, a higher level of Mathematics and proficiency in Swedish. Applications can be sent via SKY’s website, www.yhsky.se. The deadline for education starting next year is on the 15th of May 2023.

Yhteyshenkilö

SSI SCHAEFER appoints Michael Hillstrom as a new Managing Director for Nordics

On the 1st of October 2022 the SSI SCHAEFER Group has appointed Michael Hillstrom as Managing Director of the SSI SCHAEFER Nordics (Denmark, Norway, Iceland, Sweden, and Finland).

Michael Hillstrom has been working for SSI SCHAEFER for almost 10 years and has held several senior positions. From 2013 he has been Sales Director for Scandinavian countries, and since October 2019 took over the position of General Manager of Sweden and Finland. He also successfully leads the Product and Equipment business unit in the Northern Region.

Senior Vice President, Regional Head Northern Europe of SSI SCHAEFER, Jaap Vos said: "We are pleased to welcome Michael Hillstrom as Managing Director of SSI SCHAEFER Nordics. Michael has a long experience within the management team of the Nordics and can combine this with his long sales and leadership experience and personal leadership qualities and competences.”

The senior level executives of SSI SCHAEFER Group are convinced that the company's branches in Scandinavia has now again found a permanent leader with the new Managing Director.

"I look forward to starting at my new role and convey my experience to support the business development in the Nordic countries. We are now around 200 employees in Scandinavia specializing in the supply chain within warehousing and intralogistics. For the upcoming years we will focus on further optimization, innovative approach, and future proof thinking to help us realize successful projects together with our сustomers”, says Michael Hillstrom, Managing Director SSI SCHAEFER Nordics.

Yhteyshenkilö

Logistiikka-messut 2022

SSI Schäfer osallistuu Tampereen Messu- ja Urheilukeskuksessa järjestettäville Logistiikka-messuille 14.–15.9.2022.

Tervetuloa tapaamaan asiantuntijoitamme ja keskustelemaan sisälogistiikkaan liittyvistä tarpeista ja mahdollisuuksista! Löydät meidät osastolta C 2011. Myynnin, asiakaspalvelun ja projektinhallinnan asiantuntijamme – Lauri, Akseli, Tanya, Jani, Oskar ja Veikko – antavat mielellään neuvoja ja vinkkejä yrityksellenne sopivan, tehokkaan varastoratkaisun suunnitteluun ja toteutukseen.

Erikoisosaamistamme on yksilöllisten ratkaisujen suunnittelu ja toteutus asiakkaan prosessien ja tavoitellun tuottavuustason mukaisesti, sisältäen tuotteet manuaalisesta käsittelystä aina älykkäisiin, täysautomatisoituihin järjestelmiin.

Aika: 14.–15.9.2022

Paikka: Tampereen Messu- ja Urheilukeskus

Kohderyhmä: tuotantopäälliköt, operatiiviset johtajat, toimitusjohtajat, logistiikkapäälliköt ja -johtajat, liiketoiminnan kehitysjohtajat, yritysjohto

REKISTERÖIDY LOGISTIIKKA-MESSUILLE

Lisätietoa messuista

Logistiikka-messut esittelee ratkaisuja koko logistiikka- ja toimitusketjun hallintaan, varastonkiertoon sekä logistiikan ulkoistamiseen.

Toimiva logistiikka on kilpailuetu jokaiselle yritykselle. Erityisesti sisälogistiikka on nousemassa yhdeksi tärkeimmistä yritysten toiminnan kehittämisen kohteista. Messuilla näet ja kuulet alan uusimmat kehitysaskeleet maksimaalisen kilpailuedun saavuttamiseksi.

Yhteyshenkilö

LOGY Conference 2022

Lauri Impiö, Head of Sales at SSI SCHÄFER Oy, will participate in intralogistics part of the LOGY Conference – “Update Your Business – How to succeed in the New Normal”. The conference will take place on the 9th and 10th of June, 2022.

Lauri will discuss the latest trends and the impact of Covid on warehouse automation and e-commerce fulfilment:

What happened with delivery time standards and how long it should take from shopping to shipping?

When it is wise to choose person-to-goods order picking instead of growing popularity goods-to-person?

Why do supply chain issues affect the EU more and how does it reshape the warehousing industry?

What has to be considered when planning efficient returns handling? Why it is a must rather than a choice?

When: 9th and 10th of June, 2022

Where: Aalto University

Target audience: Operations Managers, COO, CEO, Logistics Managers and Directors, Business Development Directors, Business Owners

To register for visiting LOGY Conference, please CLICK HERE.

SSI SCHAEFER on track with sustainability strategy

As a partner for sustainable logistics, SSI SCHAEFER has been active on the market for years. The sustainability strategy approved in fall 2021 will be implemented step by step. It will be presented together with the Sustainability Report 2021, which will be published in summer 2022. An example is the Vertical Farming solution in cooperation with Infarm, which involves supplying sustainably for an increasingly urbanized society. This was presented for six months at the Expo in Dubai and will now be exhibited at the LogiMAT 2022 trade fair in Stuttgart (Germany) in May.

Sustainability is an important topic that companies and individuals are currently dealing with. "For the SSI SCHAEFER Group, sustainability is important in two ways: We see ourselves as a service provider offering customers innovative and sustainable intralogistics solutions, but also as a globally active company that acts with responsibility towards society, customers and employees." says Steffen Bersch, CEO of the SSI SCHAEFER Group. Last fall, the company, which is based in Neunkirchen, Siegerland (Germany) with 10,000 employees worldwide and recorded incoming orders of almost two billion euros in 2021 (an increase of 17.5 percent compared to the previous year), adopted its own sustainability strategy. It covers all four Business Units – Logistics Solutions, Products & Equipment, Customer Services and Waste & Packaging – and is scheduled to be published this summer.

In the past few months, SSI SCHAEFER presented future-proof solutions at the Expo 2020 in Dubai. Being an official partner of the German Pavilion Consortium, SSI SCHAEFER presented an innovative solution for vertical farming for the cities of the future at the CAMPUS GERMANY, which attracted more than 2.5 million visitors from 180 countries. Together with Infarm, a fast growing, urban farming company with a worldwide presence, data-controlled, modular vertical farming units were built. They serve to grow herbs and vegetables under perfect conditions, using 95 percent less water and land compared to conventional farming. The use of chemical pesticides can be completely omitted. Thus, farming can be carried out up to 400 times more efficiently than in the conventional way, measured in terms of the cultivated area.

Other customer projects also prove that SSI SCHAEFER has helped to meet customer needs even more efficiently and sustainably over the past year thanks to intelligent intralogistics solutions. One example is the new warehouse of the Bertelsmann subsidiary Arvato Supply Chain Solutions, a leading international provider of e-commerce and supply chain management solutions. As a partner and service provider, Arvato Supply Chain Solutions a.o. supplies more than 200 publishers and bookstores worldwide. For the location in Gütersloh (Germany), a new, additional picking warehouse was required in the limited footprint of just 900 square meters, which is designed for a technical performance of around 16 million books per year. Existing intralogistics systems, processes, and material flows had to be maintained for sustainability reasons. Furthermore, great importance was attached to ergonomics and user-friendliness in the design of the new picking work stations.

The project, which was implemented during running operation, was implemented in three steps: First of all, the order start in the old system was transferred and modernized. Then, the fully automated high-bay warehouse was connected to the existing and future storage systems. The third and most important project phase was building the shuttle warehouse, a further automatic warehouse for small parts that efficiently stores and retrieves items by means of shuttles. In order to optimally use the available space of only 900 square meters, the newly developed, ergonomic work stations at which the orders are put together, were placed onto the storage cube. This means that future expansion is also possible without causing any problems. The central elements of innovation and sustainability are reflected in this solution: flexible, powerful, future-proof, space-saving, energy-efficient, and ergonomic – all these objectives were successfully combined.

Logistics software such as WAMAS® or SAP solutions by SSI SCHAEFER help to optimize the energy efficiency of warehouses and logistics centers. Sustainable storage strategies can, for example, lead to shorter walking distances and higher technical performance, while economical warehouse operation ensures reduced energy consumption and wear and tear through reconfiguration that is automatically controlled by the warehouse management software. When it comes to handling returns, modern software such as WAMAS® enables the transparent tracking of returned goods and the rapid reintegration of the goods into the staging process for new orders.

Predictive maintenance also contributes to a reduced carbon footprint. Forecasts relating to individually defined maintenance intervals can be made by recording, analyzing and evaluating plant-specific data in real time. Thus, predictive maintenance eliminates unnecessary replacement of perfectly working products and components, reduces the number of service calls and makes a critical contribution towards protecting resources. The SSI SCHAEFER retrofit services get systems and installations up to date and thus extend the service life in favor of higher productivity, optimized flows of goods and energy savings.

A broad portfolio by SSI SCHAEFER that pays attention to sustainability. CEO Steffen Bersch promises: "In 2022, the SSI SCHAEFER Group will continue to focus on modular and scalable intralogistics solutions. The topic of sustainability plays a prominent role."

More Related topics

Yhteyshenkilö

![SSI_Expo 2020 Dubai_IMG_8696[2].jpg](/resource/image/895148/landscape_ratio2x1/374/0/40b531de0b05f0501feed23ab5afbf01/21EEA564BA607E2B906991B073EC7C89/ssi-expo-2020-dubai-img-8696-2-jpg-dam-image-fi-29212-.jpg)

Innovative contribution to the sustainable supply of the city of the future

Official Partner of the Consortium of the German Pavilion at Expo 2020 Dubai

Vertical Farming Solution showcase in the Future City Lab

Neunkirchen/Siegerland / Dubai December 08, 2021 - The SSI SCHAEFER Group, a German family-owned company with a history spanning more than 80 years and a leading international provider of modular warehousing and logistics solutions, will be demonstrating what the sustainable supply of food to an urbanized society can look like at Expo 2020 in Dubai, which started on October 1. As an official partner of the German Pavilion Consortium, SSI SCHAEFER will present an innovative vertical farming solution developed in cooperation with Infarm, the world’s fastest growing vertical farming company, in the City of the Future section of CAMPUS GERMANY. With its data-driven modular farming units, in which herbs and vegetables are grown under perfect conditions with 95% less water and land compared to conventional farming and without chemical pesticides, Infarm is building a global network of farms to grow and distribute fresh produce close to urban centers. Infarm’s vertical farming network already consists of more than 1400 farms in more than 50 cities worldwide.

Steffen Bersch, CEO of SSI SCHAEFER Group: "According to the United Nations forecast, around 80% of the world's population will live in cities by 2030. Together with the expected population growth and the increasing demand for food, it will be crucial to design the supply of the cities of the future in an integrative, safe and above all efficient and resource-saving way. Infarm’s Vertical Farming solution that we are presenting in the Future City Lab at the Expo, can be up to 400 times more efficient than conventional farming, measured in terms of the cultivated area. With this, the SSI SCHAEFER Group is consistently implementing its value proposition to drive its customers' sustainability globally with future-proof solutions."

Expo 2020 Dubai, the start of which has been postponed by one year due to the Corona pandemic, takes place from October 1, 2021, to March 31, 2022, under the motto "Connecting minds, shaping the future." The World Expo site is located only about 15 minutes by car from the SSI SCHAEFER office in the Dubai Logistics City area, a hub for intralogistics solutions in the Middle East and Africa. Within the German Pavilion, SSI SCHAEFER is the only member of the intralogistics industry.

The German Pavilion, whose client is the German Federal Ministry for Economic Affairs and Energy, will be showcasing sustainability at the fair. The exhibits will be grouped into the thematic areas of energy, city of the future and biodiversity. The aim of CAMPUS GERMANY is to provide visitors with solutions for a more sustainable future in a vivid way with many interactive elements.

"How do we want to live in cities in the future? The Future City Lab in the German Pavilion at Expo 2020 Dubai answers this elementary question. In this Lab, our CAMPUS GERMANY takes visitors into the city of the future and shows, among other things, how food can be produced and made available sustainably in urban spaces," says Sebastian Rosito, Deputy Commissioner General and Director of the German Pavilion at Expo 2020 Dubai.

Growing urbanization and the rapidly increasing importance of e-commerce lead to ever more complex requirements for SSI SCHAEFER's customers. This is caused by increasing expectations from consumers for the individualization of products, same-day delivery and the highest service quality. This poses ever greater challenges for the warehousing and logistics of large retail chains and online platforms. Against this backdrop, SSI SCHAEFER sees itself in the role of "enabler", contributing to meeting the needs of customers more efficiently and sustainably with intelligent intralogistics solutions in the field of digitalization and automation.

Yhteyshenkilö

LogiMAT 2022

SSI SCHAEFER presents future-proof intralogistics for dynamic requirements

Future-proof logistics systems are flexible, scalable and sustainable

Logistics software as the key to process optimization along the supply chain

SSI SCHAEFER as a reliable partner for materials handling solutions that grow with the customer

In the age of e-commerce with maximum customer orientation and many services, order structures and throughput times in intralogistics have changed drastically. In order to transfer these multi-layered requirements into efficient logistics structures, companies need flexible logistics systems that work together in a perfect network, and these need to be controlled in transparent processes by powerful logistics software. SSI SCHAEFER covers this complex range and at LogiMAT 2022, it will present how its customers achieve a competitive advantage with future-proof intralogistics. Steffen Bersch, CEO of the SSI SCHAEFER Group: "As a leading solution provider in the market, we aim to create value for our customers with innovative products, outstanding project work and in a trusting partnership that leads them safely into the intralogistics future."

At the booth in Hall 1, SSI SCHAEFER will show how small and medium-sized companies can partially automate processes in a simple way in terms of "plug & play", all at attractive costs. The result is that storage, transport and picking processes are accelerated, the available space is used more effectively, and ergonomic workflows are guaranteed. Building blocks of these solutions include automated guided vehicles, mobile racking systems, channel storage applications with the SSI ORBITER® and the SSI LOGIMAT® Vertical Lift Module, which will be exhibited at the trade fair.

Another focus is on intelligent automation solutions such as robotics applications, shuttles, and overhead conveyor technology that handle multi-layered orders within an efficient omnichannel logistics system. Among other things, solutions for the retail, fashion, healthcare & cosmetics, and production logistics sectors will be presented at the booth.

The key element of the dynamic systems is the WAMAS® logistics software, which uses real-time analyses, smart data processing and optimization algorithms to optimally control the complex processes in the warehouse and ensure seamless transparency. The modular SSI SCHAEFER software, whose quality has been officially confirmed several times, seamlessly integrates into the companies' process and system infrastructure and connects upstream and downstream systems to form an overall system. SAP solutions are also part of the software competence of SSI SCHAEFER - since the majority shareholding in SWAN in 2021, they jointly rank among the top 5 providers for SAP logistics.

A special highlight at the booth is the exhibit on the Vertical Farming solution that SSI SCHAEFER, as official partner of the German Pavilion consortium, just presented at Expo 2020 in Dubai. The innovative as well as sustainable solution was developed in cooperation with Infarm, the fast-growing urban farming company with global presence, and is now presented in Europe.

SSI SCHAEFER at the LogiMAT trade fair in Stuttgart / May 31 - June 02, 2022 / Hall 1 D21

Yhteyshenkilö

Varastointi- ja keräilyratkaisuja Mitsubishi Logisnext Europe Oy:lle

SSI SCHÄFER toimitti vuonna 2020 varastointi- ja keräilyratkaisun pitkäaikaiselle kumppanilleen, Mitsubishi Logisnext Europe Oy:lle (aiemmin Rocla Oy), joka lukeutuu automaattitrukkiratkaisujen markkinajohtajiin. Toimitus piti sisällään lavahyllystöjärjestelmän sekä varastoautomaattiteknologiaa.

Muutosten tausta

Vuonna 2013 Mitsubishi Logisnext Europe, joka oli tuohon aikaan nimeltään vielä Rocla, teki strategisen päätöksen laajentaa tuotantotilojaan Suomessa. Yritys halusi toteuttaa suunnitelmansa nopeasti ja vuokrasi siksi useita pieniä varastotiloja. Tiloihin varastoitiin sekä pienikokoisia tuotteita että kuormalavoille lavattuja suurempia tuotteita, odottamaan käyttöä tuotannossa. Strategiaa tarkasteltiin uudelleen vuonna 2020, jolloin syntyi päätös hankkia yksi yhtenäinen varastotila läheltä tuotantotiloja, Järvenpäästä. Muutos oli kuitenkin toteutettava pikavauhdilla – sen oli oltava valmis kolmessa kuukaudessa.

Asiakkaan visio ja selkeät odotukset

Vuonna 2020 Mitsubishi Logisnext Europella oli omat, selkeät odotuksensa ja visionsa. Yrityksessä tiedettiin liiketoiminnalliset vaatimukset ja aikataulut. Ainoa avoin asia oli oikean kumppanin löytäminen hankkeeseen.

“Meillä oli tyhjä rakennus, johon tarvitsimme tehokkaan, tilaa optimaalisesti hyödyntävän järjestelmän. Lisäksi tarvitsimme aiempaa nopeamman keräilyratkaisun”, kertoo Anssi Haataja, Mitsubishi Logisnext Europe Oy:n Senior Manager of Industrial Technology & Premises.

Yksi tärkeimmistä syistä varastotilojen yhdistämiseen oli kasvava tilantarve. Lisäksi haluttiin selkeä varastonäkymä sekä läpinäkyvät prosessit. Kaikella tällä tavoiteltiin parempaa tuottavuutta, joka näkyisi viime kädessä myös tyytyväisempinä loppuasiakkaina. Projektissa painetta lisäsi erityisesti tiukka aikataulu, joka ei sallinut muutoksia tai viivytyksiä. Mitsubishi Logisnext Europella oli käytettävissään vain kolme kuukautta tilauksen vahvistamisesta varaston käyttöönottoon täydellä kapasiteetilla.

Kaikki yhdessä paikassa

Aiemmissa vuokratiloissa oli asennettuna vain hyllyjä, ei automaatiotyökaluja tai älylaitteita. Järjestelmän “aivoina” toimi silloinen, yksinkertainen ERP-järjestelmä. Koska tuottavuutta haluttiin parantaa, ensiaskeleena päätettiin ottaa käyttöön varastonhallintajärjestelmä.

Uusi, 8 500 neliömetriä kattava rakennus on jaettu puoliksi automaattitrukkien testialueeksi ja varastotilaksi. Kun tavaraa otetaan vastaan, tiedot syötetään saman tien varastonhallintajärjestelmään. Tavarat lähetetään joko puskuriin tai varastopaikoilleen. Uusi järjestelmä sisältää kaikkiaan kymmenen SSI LOGIMAT® -moduulia. Kahdeksaa niistä käytetään pientavaroiden, kuten pulttien ja kannatinten, varastointiin. Kahta muuta moduulia käytetään suurempien osien varastointiin. Yksi työntekijä voi käyttää samanaikaisesti neljää SSI LOGIMAT® -moduulia.

“Varastonhallintajärjestelmän avulla pystymme hyödyntämään kaikkia neljää moduulia kerralla ja keräillä niistä tarvittavat osat. Kun tarvittavat osat on poimittu yhdeltä varastoalustalta, toinen alusta on jo tulossa käyttöaukolle”, kertoo Warehouse Manager Marko Lappi Mitsubishi Logisnext Europelta.

Varastoautomaateissa on tällä hetkellä 22 000 nimikettä ja yhteensä yli 1,1 miljoonaa osaa. Yhtäaikainen vuorovaikutus moduulien kanssa mahdollistaa erilaisten tuotteiden samanaikaisen varastoinnin ja säästää siten työaikaa.

Varasto sisältää myös SSI SCHÄFERin PR 600 -lavahyllystöjä kuormalavojen varastointiin. Mitsubishi Logisnext Europella on kyseisellä varastoalueella paikat 5 000 kuormalavalle.

Tavarankulku on suunniteltu niin, että keräilyssä poimitaan ensin tuotteet SSI LOGIMAT® -moduuleista ja sitten PR 600 -hyllystöiltä. Tämän jälkeen kerätyt tuotteet yhdistellään ja lähetetään sitten tuotantolinjalle.

Helppoa ylläpitoa

Kun varastojärjestelmää oltiin tilaamassa, Mitsubishi Logisnext Europe arvioi tarjotut ratkaisut neljän pääkriteerin mukaan: haluttu varastopaikkamäärä, asennuksen ja integroinnin helppous, tarvittavan tuottavuustason varmistus sekä projektin valmistuminen ajallaan. SSI SCHÄFER täytti kaikki vaatimukset.

“SSI SCHÄFERillä oli myös oma asennustiiminsä, joten päätimme edistää projektia heidän kanssaan”, Haataja toteaa.

Mitsubishi Logisnext Europe sai myös pidennetyn, viiden vuoden takuun sekä ylläpitosopimuksen. Yritykselle on kriittisen tärkeää varmistaa, että varastossa voidaan tehdä töitä sujuvasti, jatkuvasti ja ilman häiriöitä.

“Ylläpitotiimi sijaitsee lähellä toimitilojamme ja on tarvittaessa valmis tukemaan meitä nopeasti”, Lappi kertoo.

Tuotteet

Yhteyshenkilö

SSI SCHAEFER proud to partner with Coca-Cola Amatil

SSI SCHAEFER is proud to have partnered with Coca-Cola Amatil to deliver their automated state-of-the-art facility featured in a series of recent corporate videos, released by Coca-Cola Amatil, one of the largest bottlers and distributors of beverages in the Asia Pacific region.

Video: „Innovation and Automation.“ A world-class brand and world-class automation.

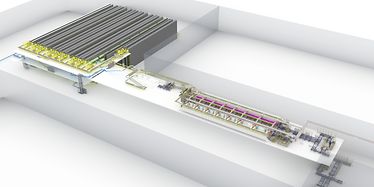

Following an open request for tenders by Coca-Cola Amatil, SSI SCHAEFER‘s recommended solution was selected for the state-of-the-art 30,000m2 distribution center in Brisbane, Australia. Working closely with Coca-Cola Amatil and backed by SSI SCHAEFER’s extensive experience in mixed case robotic palletizing, a concept was created which matched Coca-Cola Amatil‘s priorities for the site of having a flexible, agile and accurate system that supported the delivery profile of their business as well as the storage capacity and necessary throughput. Providing a system that met the proud safety culture of Coca-Cola Amatil was also a priority. The concept integrated both case picking with bulk storage and delivers a very flexible system, with both high utilization and availability, picking more than 2.5 million cases annually.

Anthony Lee Project Manager Major Works for Coca-Cola Amatil

“I think SSI SCHAEFER were very collaborative as we moved through the design. They brought a lot of their expertise that they gained from around the world in helping us develop this facility. “

Storage density with high throughput

The SSI SCHAEFER design features their unique SSI Lift&Run technology which provides high storage density at the same time as high throughput. The SSI Lift&Run High Bay Warehouse (HBW) receives full pallets via an airbridge directly from the adjacent bottling plant. The system provides for the automatic storage and retrieval of more than 30,000 pallets over 7 levels and includes 12 SSI Lift&Run cranes in 4 aisles and an extensive pallet conveyor system with multiple pallet lifts.

Agile and accurate system

Adjacent to the SSI Lift&Run High Bay Warehouse, SSI SCHAEFER installed an Automatic Case Picking (ACP) system. The proximity and direct link to the HBW enables automatic pallet replenishment direct from the HBW. Full pallets are conveyed to the ACP from the Automated Storage and Retrieval System (ASRS) where they are automatically delayered by a depalletizing robot, case wheeler and Intralox case singulation. The individual cases are then stored directly in a 3-aisle SSI Cuby trayless shuttle case buffer system.

Increased safety

Required cases are sequenced out of the SSI Cuby case buffer to one of three robots for automatic palletizing. The robot palletizes the fastest moving top 30 SKUs for Coca-Cola Amatil’s route trade, picking over 2.5 million cases annually.

Tom Scheibling, Supply Chain for Coca-Cola Amatil

“50% of our manual handling tasks have been automated in this site which ultimately means less manual handling injuries and less risk to manual handling, driven by the automation.“

Emily Smeed, Inventory Manager for Coca-Cola Amatil

“It removes the need for a lot of forklift interaction; it removes the need for any manual handling. The more we are putting into the automation the less we are having to expose to our employees on the floor.“

Flexible system supporting their business model

All components are controlled by SSI SCHAEFER’s WAMAS® Warehouse Control System which interfaces directly to Coca-Cola Amatil’s SAP host EWM system. This includes SSI SCHAEFER’s world leading SCHAEFER Pack Pattern Generator (SPPG) module, which is responsible for building stable and dense pallets.

Ensuring best system performance

A key aspect to ensuring the best performance of the system is the SSI Resident Maintenance® team who not only maintain the equipment in direct consultation with their Coca-Cola Amatil partners, but also continue to optimize and improve reliability and throughput. Through SSI SCHAEFER’s Computerized Maintenance Management System (CMMS), all actions by the maintenance team are captured and logged using handheld terminals, building up a database of root causes for all stoppages which feeds into collaborative continuous improvement actions for the maintenance and operations teams.

The design provided Coca-Cola Amatil with a compact yet resilient automated storage solution which allowed it to meet its goal of implementing a new warehouse on the production site, with an airbridge conveyor link directly from production. The solution met all of Coca-Cola Amatil’s requirements in terms of storage, throughput, expandability and redundancy.

Anthony Lee, Project Manager Major Works for Coca-Cola Amatil said

“SSI SCHAEFER were really committed to making sure the facility worked, and ultimately we have produced a facility that has some of the highest utilization and availability that I have seen anywhere.“

Yhteyshenkilö

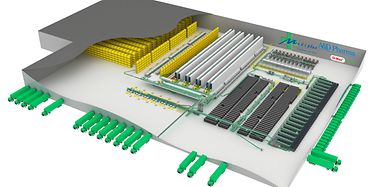

Grocery, Logistics, Sustainability: Customised Solution for Absolute Sequence

Back in 2017 NorgesGruppen ASA, one of the leading retail groups in Scandinavia, commissioned SSI SCHAEFER to build a new logistics center for its subsidiary company ASKO OSLOFJORD AS (ASKO).

Knut-Andreas Kran, CEO of ASKO OSLOFJORD AS, comments on the challenges the company experienced at the time: “ASKO anticipated a future capacity problem with only two possible solutions: either to extend the existing building or to relocate. We simply would not be able to keep up with the expected growth in the current location. We also did not want to just build a larger manual warehouse as we see that automation is an investment in the future.”

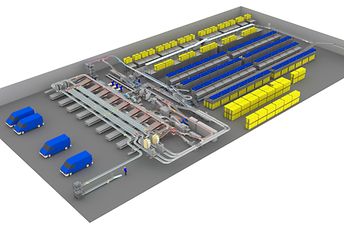

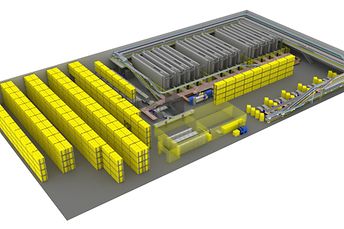

The new logistics center is designed to handle the highly dynamic storage and picking of groceries from the dry and frozen food’s segments. To achieve this, SSI SCHAEFER is building two high-bay warehouses, and two highly dynamic shuttle warehouses based on the 3D-MATRIX Solution®. Robot technology is also deployed to support automated material flow.

Both, ASKO and SSI SCHAEFER realize the responsibility tied to every large project not only in terms of well-build operations and product quality but also sustainability. Sustainability is building into an absolute must-have for all companies, across all industries. 62% of top management across different sectors believe that one needs a solid sustainability-oriented strategy to survive the competition. Briefly, a sustainable business approach means minding ecological, social, and economic environments and influence on them while organising your company’s operational activities. (Source: IMD, 2016)

Just like with overall strategy there is no correct answer to sustainability. The best solution depends on the ambitions and stakes of each company.

Scandinavian way of business: Best practice of ASKO

ASKO has been on the market for more than 150 years promoting and supporting their core values and delivering high-quality and functional products to its customers. The retail company believes that quality should always walk hand in hand with a focus on sustainability.

Knut-Andreas Kran shares their 3 main sustainability goals: “First of all, we want to be climate neutral and sustainable as a company. We also aim at using 100% renewable energy and fuels for our trucks within 2026. The last but not the least, we want to reduce our energy use by 20%, mainly in the warehouses.”

ASKO is known to be the leading company in the green revolution with a wide range of sustainable initiatives they follow and apply. The ambitious goals come with patience and a plan of actions. ASKO heavily invests in solar panels and land-based windmills, testing multiple options and learning from the experience. Realizing the opportunities and responsibility they have as a large organization, a few years back ASKO launched an environmental engagement initiative for the employee’s private life. They arranged a Climate fund, where an employee can apply for financial support for sustainable activities in their homes or support for travelling to and from work in a climate positive way. The employees can apply for partly sponsoring of an electrical bike, electric car, installing isolation at home or solar panels in their homes. In the last years, this has been an initiative that a lot of the Employees apply for and has led to great results of the engagement.

On the right track: SSI SCHAEFER

The SSI SCHAEFER Group is the world’s leading material handling company. Operating across six continents, SSI SCHAEFER designs, develops and manufactures innovative solutions tailor-made for customers’ needs and challenges. As intralogistics serves as a foundation for companies operating in various sectors, for those companies being green starts right there.

Intralogistics works with a wide spectrum of areas and therefore can introduce sustainability in many different ways. Therefore, SSI SCHAEFER is offering and providing an extensive range of economical and resource-friendly solutions, based on innovative technology. For example, containers made from recyclable materials, energy-saving equipment like SSI Exyz storage-retrieval machine and even software build to control and monitor operations with optimal energy use. The storage-retrieval machines are extremely compact in design. In combination with an optimized control system, this significantly reduces the space required: compared to conventional high-bay warehouses, an installation space saving of up to 5% can be achieved. That is many cubic meters that do not need to be built, heated, or air-conditioned. In addition to the space savings, the control pendants are also characterized by high energy efficiency, as the counterweights integrated into the mast significantly reduce the energy requirement in the hoist compared to any energy recovery gains. SSI SCHAEFER realizes how crucial it is to consider every possible option to save, preserve and optimize – in terms of automation, costs, and sustainability.

“We want to be responsible in the way we interact with the environment. Our goal for the future is not to consume more natural resources than supplied in the natural cycle.” – comments Johannes Zimmermann, Director Construction Management at SSI SCHAEFER.

Being responsible also means to never lose focus and keep working for better and greener solutions. To do more, in 2020 SSI SCHAEFER was the first material handling company to join 50 Sustainability and Climate Leaders initiative. The initiative is targeted to form the international businesses willing and aiming at fighting against climate change and to meeting the United Nations 17 Sustainable Development Goals (UNSDG).

It is a match! How did the partnership start?

“It is important for us that a supplier complies with all the regulations. We need to know that they follow the same sustainability goals as we do. First, we ask whether they have a sustainability-oriented programme. If the answer is yes, then we can have a further discussion,” comments Knut-Andreas Kran.

This position is not unusual for the Nordic region and is getting more attention across different sectors opening various possibilities for companies to contribute to long-term, future-proof, and sustainable values. It was SSI SCHAEFER’s determination for conducting greener business to strongly play in favour of choosing them as a general contractor. For ASKO with their ambitious sustainability goals and a heavy focus on climate neutrality, SSI SCHAEFER was a match.

A foundation for any business model: A new regional logistics distribution center for ASKO

As a general contractor, SSI SCHAEFER is responsible for developing the logistics concept, the design planning, and the construction of the turn-key installation for the retail company ASKO. The overall project includes a comprehensive infrastructure with material flow management, visualization, and a warehouse management system.

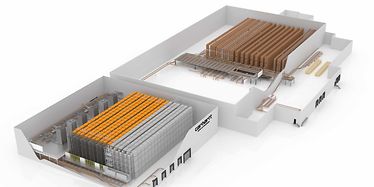

The highly automated distribution center is located at Sande, approximately 60 km south of Oslo, Norway, and is split into two different temperature zones: ambient and frozen with 28,700 overall pallet storage locations, highly efficient cross-dock and consolidation areas.

The frozen area incorporates a two-aisle high-bay warehouse (HBW) with SSI Exyz type storage-retrieval machines. The HBW in the frozen area is dedicated for double-deep storage at -28 °C at 3,696 storage locations. With the focus on sustainability, new technology development and client’s increased requirements SSI SCHAEFER decided to change initially picked SSI Miniload Cranes with 84 SSI Flexi shuttles in the frozen area as they were a better fit for the role. After manual depalletizing SSI Flexi shuttles are responsible for storage and retrieval of containers from shelves.

The ambient area incorporates a high-bay warehouse with eight SSI Exyz type storage-retrieval machines as well as a 90,000 locations SSI Navette system with 64 multi-level shuttles for small load carriers and 80 lifts ensures processes are as efficient as possible. The depalletizing required to store the goods in the highly dynamic shuttle warehouse will be fully automated and carried out by two robots. The design of both shuttle warehouses - in the frozen as well as in the ambient area - are based on the 3D-MATRIX Solution®, that enables storage, buffering, and sequencing in one system. This allows cases that were previously put into temporary storage to be handed over to the palletizing robots in an exact sequence.

With the number of different functional areas on the premises, a wide range of pallet and bin conveying systems link them to each other and to the 6-level shipping buffer. The material flow between the areas as well and stock and order management is coordinated by WAMAS®, logistics software from SSI SCHAEFER. Thanks to WAMAS capacity utilization can be tracked and optimized at any time.

Every successful cooperation requires active listening, compromises, and flexibility, especially with the uncertainty businesses faced in 2020. When a company has solid values, like ASKO with its ambitious sustainability goals, a partner should always strive to deliver the most efficient solution. A great example here is the change from SSI Miniload cranes to SSI Flexi shuttles. During the ongoing project, new technology was introduced to the market – SSI Flexi shuttle. The innovative energy supply for the shuttle uses supercapacitors to ensure the highest energy efficiency. It was anticipated to serve better for ASKO’s needs and provide a highly sustainable solution for the frozen products zone. Therefore, in no time it was offered to the client and accepted in the project scope.

The project is expected to be fully completed in 2021.

Recent events taught business community that agility is one of the most demanded skills of any survival kit. Being flexible in your offering, terms and conditions, and almost every single aspect of your operations is simply a new normal and not an extra effort anymore. Realizing this, SSI SCHAEFER strives to keep a high level of flexibility in their work. Therefore, future system extensions are already included in the initial layout so that the system can adapt to market requirements immediately and easily. It served well for the current project with ASKO.

Sustainability is the hottest topic in any boardroom. It is not the question of whether to join or stall but the way that will work for the company better in terms of ROI and future-proof products and solutions. It is about forming long-term partnerships without compromises where it matters the most. Like ASKO choosing SSI SCHAEFER as a general contractor for their focus on recyclable materials, green technology, and ergonomic approach in layout design.

Yhteyshenkilö

Kokkikartano ja SSI SCHÄFER allekirjoittivat sopimuksen automaatiotoimituksesta

Snellmanin Kokkikartano Oy tunnetaan kotiruokareseptein valmistetuista valmisruuistaan. Kun Kokkikartano päätti rakentaa uuden logistiikkakeskuksen, se halusi kertatoimituksen sijaan löytää pitkäaikaisen kumppanin. Yhtiö halusi aloittaa yhteistyön, joka jatkuisi vuosikymmeniä eteenpäin ja jonka aikana useat yhdessä toteutetut projektit tukisivat yrityksen kasvuvauhtia ja sisälogistiikan muuttuvia tarpeita.

Uuteen, pinta-alaltaan noin 3 000 neliömetrin rakennukseen tulee shuttle tekniikalla toteutettu automatisoitu varasto, kuljetinjärjestelmä sekä keräilyteknologiaa. Näin tuottavuus saadaan maksimoitua jokaisella toiminta-alueella. Uusi järjestelmä tukee osaltaan Kokkikartanon tavoitetta tuplata volyyminsa tulevan 10 vuoden aikana.

Yhteinen perusta ja pikastartti yhteistyölle

Laatu, asiakaspalvelu ja kotiruuan aitous ovat Kokkikartanon kolme ydinarvoa, joista halutaan pitää kiinni. SSI Schäfer, joka on yhtä lailla perheomisteinen yhtiö, ymmärtää ja jakaa samojen seikkojen tärkeyden ja perustavanlaatuisen arvon. Myös SSI Schäfer pitää laatua työnsä tärkeimpänä periaatteena.

Tärkeää kumppanuuden aloittamisessa oli myös se, että SSI Schäfer pystyy toimittamaan kokonaisratkaisun, varmistamaan laadun sekä räätälöimään järjestelmän palvelemaan Kokkikartanon liiketoiminnan prosesseja ja tarpeita yhä paremmin.

“SSI Schäferillä on vahva paikallinen organisaatio Suomessa. Jos meillä on mitä tahansa kysyttävää järjestelmän käyttöönoton jälkeen, meidän on helppoa ja nopeaa ottaa yhteyttä paikalliseen tiimiin”, kertoo Kokkikartanon tuotantojohtaja Tea Tilander.

Täydellinen prosessi

Kokkikartano arvioi nykyisiä prosessejaan ja saatavilla olevia resurssejaan vuonna 2021, ja määritteli tarpeen pitkälle automatisoituun materiaalinkäsittelyratkaisuun uusiin toimitiloihinsa Keravalle.

“Nykyinen varastomme toimii täysin manuaalisen työn pohjalta ja varastotilasta on aitoa pulaa. Meidän on ollut pakko ulkoistaa osa varastoinnista, jotta olemme pysyneet kysynnän perässä”, Tilander kertoo.

Uudessa automatisoidussa ratkaisussa tavarat saapuvat tuotantolinjalta kuljetinta pitkin ja jatkavat joko varastoon, keräilyyn tai suoraan lähetykseen. Tuotteet voidaan sijoittaa kaksikäytäväiseen, SSI Flexi -shuttleja hyödyntävään automatisoituun varastoon odottamaan noutoa tilausta varten. SSI Flexi sisältää yli 40 000 varastopaikkaa ja mahdollistaa lisätilan myös tulevalle kasvulle liiketoiminnan kehittyessä.

Vaihtoehtoisesti tuotteet voidaan kuljettaa suoraan keräilyalueelle kuljetinlinjaa pitkin. Tilaukset keräillään manuaalisesti hyödyntäen valo-ohjattua pick by light -keräilyteknologiaa. Näin keräily on nopeampaa ja virheetöntä. Tuotteet toimitetaan oikealle alueelle kuljetinjärjestelmän avulla.

Seuraavaksi keräillyt tuotteet siirretään alakertaan lavausalueelle, jossa ne lavataan ja lähetetään sitten asiakkaille.

Tulevaisuus mielessä

Kokkikartanon uudessa ratkaisussa on 50 % enemmän varastopaikkoja nykytiloihin verrattuna. Jatkossa järjestelmää laajennetaan Kokkikartanon kasvuvauhdin mukaisesti.

Ratkaisu luovutetaan Kokkikartanolle kesällä 2023.

Yhteyshenkilö

Miksi ja miten Coop siirtyy manuaalisista toiminnoista kohti automaatiota

Manuaalisesta varastosta, yhteen maailman suurimmista automatisoiduista jakelukeskuksista

Ruotsin johtaviin elintarvikealan vähittäiskauppaketjuihin lukeutuva Coop ja yksi maailman johtavista sisälogistiikan tuotteiden ja järjestelmien ratkaisutoimittajista, SSI Schäfer, ilmoittivat lokakuussa 2020 aloittavansa pitkäaikaisen yhteistyön.

Jututimme Coopin strategisten toimitusketjujen projektipäällikköä Mats Tornardia hankkeesta, sen nykytilasta sekä Coopin tulevaisuuden tavoitteista. Mats avasi hankintapäätöksen taustoja ja kertoi, miten ja miksi Coopilla päätettiin siirtyä täysin manuaalisesta varastosta yhteen maailman suurimmista automatisoiduista jakelukeskuksista.

”Toimialallamme on nähty monta siirtymää kohti automaatiota. Automatisoitujen prosessien mahdollistamiin tuottavuustasoihin on käytännössä mahdotonta yltää manuaalisella käsittelyllä.” – Mats Tornard toteaa.

Coop teki strategisen päätöksen investoida uuteen, pitkälle automatisoituun logistiikkakeskukseen. Taustalla oli muun muassa työntekijöiden työympäristöön, yrityksen pitkän aikavälin kehitykseen ja jatkuvaan tehokkuuteen liittyviä pohdintoja.

Varastosaldot kohdillaan: kuinka 77 000 m2 kattava järjestelmä toimii

Jos organisaatiolla on selvät ja tinkimättömät arvot, ne on syytä kirjata ylös ennen laajan projektin aloittamista. Näin teki myös Coop, joka halusi pitää hankkeen pääfokuksen henkilöstössä ja kestävässä kehityksessä. Nämä arvot pidettiin mielessä jokaisen päätöksen yhteydessä. Esimerkiksi tavaratoimitukset linkitetään valtakunnalliseen rautatieverkostoon, jolloin saadaan vähennettyä autojen käyttöä ja siten pienennettyä hiilijalanjälkeä.

Suurin osa tuotteista saapuu jakelukeskukseen junalla, ja ne puretaan sisäänsyöttöalueen välittömässä läheisyydessä. Tavaroiden vastaanottoalueella on kuljetinjärjestelmä, joka sisältää laaduntarkastuspisteen sekä lavantarkastusaseman, joilla varmistetaan lavojen oikeanlainen käärintä ja tukevuus. Tämän jälkeen tuotteet toimitetaan korkeavarastoon säilytettäviksi, kunnes niitä tarvitaan keräilyssä. Tilaukseen tarvittavat lavat saapuvat lavanpurkuasemalle, jossa tuotteet jaetaan yksittäisiin laatikoihin säilytettäväksi tulevia asiakastoimituksia varten.

Asiakkaan “keräilyvarastoksi” kutsuma SSI Schäferin 3D-MATRIXSolution® hoitaa laatikkojen varastoinnin. Varastopaikkoja hallinnoidaan SSI Flexi -shuttleilla, joilla hoidetaan varaston täydennys ja tuotenoudot. Asiakastilauksien lavauskuviot muodostetaan automaattisesti etukäteen, ja niitä hallitaan SSI Schäferin omalla WAMAS®-logistiikkaohjelmistolla tilausten sisältöjen mukaisesti. Näin taataan lavojen tukevuus sekä maksimaalinen täyttöaste. SSI Flexi siirtää laatikot lavausasemalle, jossa lavausrobotti hoitaa tilausten kokoamisen lähetystä varten.

Valmiit lavat toimitetaan lähetyspuskuriin, jossa kaikki tietylle asiakkaalle tai tiettyyn kohteeseen toimitettavat lähetykset yhdistetään odottamaan noutoa. Rekkojen saavuttua lavat toimitetaan lähettämön oville oikeassa lastausjärjestyksessä.

”Asioiden helpoksi tekeminen on joskus monimutkaista. Minusta olemme kuitenkin onnistuneet rakentamaan yhdessä uskomattoman hienon ratkaisun.” – Mats Tornard kertoo hymyillen.

Tästä olemme täsmälleen samaa mieltä.

Nykytilanne

”Kaikista pandemian mukanaan tuomista haasteista huolimatta projekti etenee aikataulussa eikä viiveitä ole tähän mennessä ollut ollenkaan.” – Mats Tornard kertoo.

”Olemme juuri saaneet valmiiksi jakelukeskuksen rakennustyöt. SSI Schäfer rakentaa parhaillaan korkeavarastoa ja SSI Flexin shuttlehyllystöä. Samalla suunnittelemme uudelleen myös sisäisiä prosessejamme, jotta saamme hyödynnettyä uutta järjestelmää parhaalla mahdollisella tavalla.”

Pitkäaikaista yhteistyötä, pitkäaikaista hyötyä

”On hienoa, että molemmissa yrityksissä nähdään yhteistyö nimenomaan pitkäaikaisena kumppanuutena. Meitä ilahduttaa, että SSI Schäfer esittelee aina uusimpia ratkaisujaan – myös niitä, jotka eivät olleet vielä saatavilla esimerkiksi suunnitteluvaiheessa tai pohjaratkaisua piirrettäessä. Tällainen proaktiivinen ja innovatiivinen ajattelu auttaa meitä hyödyntämään jakelukeskuksemme täyden potentiaalin.”

Uudet tilat auttavat Coopia tehostamaan toimitusketjuaan. Coop saa nostettua merkittävästi päivittäistä lähetysmääräänsä, parannettua saavutettavuutta sekä ajoitettua lähetykset tarkasti parempien rautatieyhteyksien ansiosta.

Coop pyrkii lyhentämään tavaroiden purkamiseen kuluvaa aikaa myymälöissä. Siksi se toimittaa tuotteet asiakasystävällisillä lavoilla ja delegoi lavoille lastaamisen roboteille, jotka toimivat osana SSI Case Picking -järjestelmää. Näin varmistetaan aiempaa nopeampi ja järjestelmällisempi keräily lavoille.

Yksi uuden ratkaisun suurimmista eduista on se, että se parantaa työskentely-ympäristön turvallisuutta ja ergonomiaa. Nykyisessä varastossa kaikki toiminnot hoidetaan manuaalisesti, mukaan lukien raskaiden kuormien nostot ja siirtelyt. Kun uusi varastoratkaisu on otettu käyttöön, suurin osa haastavimmista työtehtävistä hoituu automaatiolaitteiden avulla ja vaatii työntekijöiltä lähinnä seurantaa ja toimintojen hallintaa. Näin Coop ja sen henkilöstö voivat keskittää huomionsa potentiaalisista terveysriskeistä strategiseen ajatteluun ja toiminnan jatkokehittämiseen.

Juuri näin tukitoimintojen, eli sisälogistiikan ja toimitusketjun, tulisikin toimia.

Meillä on vastuu – kestävä tulevaisuus on käsissämme

”Kestävä kehitys on yksi Coopin ydinarvoista” – Mats kertoo.

Ja asia on ollut näin jo kauan. Jo 30 vuotta sitten Coop oli Ruotsin ensimmäinen elintarvikealan ketju, joka lanseerasi oman luomubrändinsä, Änglamarkin. Brändi on Ruotsissa erittäin tunnettu, ja se on säilyttänyt vuosien mittaan alkuperäisen arvonsa – ympäristöystävällisyyden. Änglamark nimettiinkin vuoden 2020 Sustainable Brand Index -listauksessa Ruotsin kestävimmäksi brändiksi. Myös tänä vuonna palkinto meni Coopille.

Mats jatkaa – ”Mietimme aina ympäristöystävällisyyttä ja ekologisia näkökohtia ennen uuden projektin aloittamista.”

Samaa lähestymistapaa noudattaa myös SSI Schäfer. Vuonna 2020 SSI Schäfer liittyi 50 Sustainability and Climate Leaders -ohjelmaan ensimmäisenä materiaalikäsittelyalan yrityksenä. Ohjelman tavoitteena on taistella ilmastonmuutosta vastaan ja edistää YK:n kestävän kehityksen tavoiteohjelmaa (UNSDG). Ohjelmassa kannustetaan osallistujia hyödyntämään innovaatioita ja kestävän kehityksen mukaisia liiketoimintamalleja. Coopin uusi logistiikkakeskus toteuttaa kestävän kehityksen konseptia, mikä tarkoittaa sitä, että rakennustyömaalla käytetään vain sertifioituja ja hyväksyttyjä materiaaleja, maaleja ja komponentteja.

Uusi ratkaisu tuo enemmän kestävyyshyötyjä myös yritykselle itselleen. Yhdistämällä huoneenlämpöiset alueet ja kylmävarastot samaan logistiikkakeskukseen Coop säästää kuljetusten määrässä ja pienentää siten hiilijalanjälkeään.

Ympäristösyistä Coop vastaanottaa tavaroita junilla jo nyt. Uuden jakelukeskuksen käyttöönoton myötä junakapasiteetti tuplataan ja kahdet junaraiteet johtavat aivan varaston viereen, jotta lähetysten purkaminen hoituu jouhevasti ja nopeasti. Junissa hyödynnetään suurin sallittu pituus, minkä ansiosta Coop pystyy vastaamaan myös tulevaisuuden kasvavaan kysyntään ilman muunlaisia kuljetustapoja, esimerkiksi rekkoja.

”Coop kulkee yrityksenä omia polkujaan, se noudattaa kestävän kehityksen periaatteita ja huolehtii lämmöllä työntekijöistään. Me SSI Schäferillä jaamme samat arvot, mikä onkin yksi syy menestyksekkäälle ja saumattomalle yhteistyöllemme. Meille on ilo olla mukana tässä innostavassa hankkeessa” – toteaa SSI Schäfer Ruotsin toimitusjohtaja Michael Hillström.

Yhteyshenkilö

Automatisoitu logistiikkaratkaisu vauhdittaa Schoun kasvavaa liiketoimintaa

Tanskalainen Schou on Skandinavian suurin non-food-sektorin tukkuliike. Sen tuotekategorioita ovat kodin ja puutarhan tuotteet sekä vapaa-ajan tarvikkeet ja työkalut, ja asiakaskuntaan kuuluu muun muassa valtaosa pohjoismaisista vähittäismyyntiketjuista sekä ulkomaisia vähittäiskauppoja.

Schou valitsi SSI SCHÄFERin pääurakoitsijaksi uudelle automatisoidulle logistiikkakeskukselleen Tanskan Koldingissa. Valinta kohdistui SSI SCHÄFERiin erityisesti joustavan valikoiman ja ratkaisukeskeisen lähestymistavan ansiosta. SSI SCHÄFER ehdotti muutamaa ratkaisevaa muutosta uuden varastotilan pohjaratkaisuun, jotta lopputuloksesta saadaan mahdollisimman tehokas ja kulut optimoitua.

Tähän asti Schou on hoitanut logistiikkansa manuaalisesta varastosta käsin. Yrityksessä tunnistettiin tarve prosessien automatisoinnille, sillä liiketoiminta on kasvussa ja suunnitelmissa on myös liiketoiminnan laajentaminen. Automaatio auttaa säästämään kuluissa ja hyödyntämään nykyisiä tiloja mahdollisimman tehokkaasti. Manuaalisten hyllyjen maksimikorkeus asettuu 12 metriin, kun taas automatisoiduissa varastoissa se on käytännössä rajaton. Heti kun uudet tilat valmistuvat, Schou siirtää sinne koko toimintansa ja varastonsa useasta pienemmästä manuaalisesta logistiikkakeskuksesta.

Uusi rakennus jakautuu seitsemään alueeseen, joissa hoidetaan tuotteiden koko käsittely vastaanotosta asiakastoimituksiin. SSI SCHÄFER toimittaa Schoulle alueista viisi ja siten korkeavarastoon rakentuu kaikkiaan 39 792 varastopaikkaa.

Vastaanottoalueelle asennetaan käärintäkone, jolla kuormalavat kääritään muoviin, ja varmistetaan siten tuotteiden turvallinen siirtely ja säilytys. Kuljetinjärjestelmä vie lavat automatisoituun, 42 metrin korkuiseen korkeavarastoon. Lavoja käsitellään kuudella Exyz-hyllystöhissillä ja varastoidaan tuplasyviin varastopaikkoihin.

Schou halusi SSI SCHÄFERiltä kaksi erillistä lähettämöaluetta – automatisoidun lähetysalueen sekä erillisen alueen kampanjatuotteiden keräilyyn. Kampanjatuotteiden aluetta käytetään jatkossa suurten myyntivolyymien ja erikoiskampanjoiden yhteydessä, ja se on suunniteltu manuaaliseen trukkipoimintaan. Alueella on 60 varastopaikkaa keräilyä varten. Paikat täytetään kuitenkin automaattisesti, jotta vältetään tuotteiden loppuminen keräilyalueelta. Automatisoitu lähetysalue sijaitsee kuljetusautojen noutoportteja vastapäätä ja sisältää seitsemän kuljetinta lähtevien tuotteiden puskurointiin.

SSI SCHÄFERin toimittama uusi varasto palvelee koko toimitusketjun kattavana logistiikkakeskuksena, joka tukee tehokkaasti Schoun liiketoimintaa. Projekti valmistuu ja varasto luovutetaan asiakkaalle kesällä 2023.

Yhteyshenkilö

Marja Bothnia Berries Oy:n varastointiratkaisu säilyttää marjojen parhaat puolet

Tarjoilemme asiakkaillemme vain tuoreimpia marjoja, ja niitä riittää kaikille!

SSI Schäfer toteutti Marja Bothnia Berriesille joustavan ja kompaktin pakkasvarastointiratkaisun yrityksen uusiin varastotiloihin Mustasaareen.

Marja Bothnia Berries on tunnettu tukkuliike, joka myy pakastemarjoja, muun muassa puolukkaa, mustikkaa ja karpaloa. Yritys hoitaa koko toimitusketjun tuoreena metsästä poimituista marjoista tarjoilupöytään asti: poiminnan, puhdistuksen, pakastuksen ja asiakastoimitukset.

Liiketoiminta kattaa niin kotimaan markkinat kuin vienninkin. Marja Bothnia Berriesin uusi varasto palvelee suurten volyymien käsittelyssä, ja se auttaa varmistamaan sujuvan liiketoiminnan myös kasvavassa kysynnässä ja yrityksen laajentumissuunnitelmia ajatellen.

SSI Schäfer valittiin varastointijärjestelmän toteuttajaksi kahdesta syystä. Ensinnäkin SSI Schäfer tunnetaan markkinoilla luotettavana kylmäketjujen ja pakastettujen elintarvikkeiden varastointi- ja käsittelyratkaisujen toimittajana. Toisekseen sillä on yhteistä arvopohjaa Marja Bothnia Berriesin kanssa – kumpikin painottaa liiketoiminnassaan kestävää kehitystä.

Marja Bothnia Berriesin uusissa tiloissa on nyt aiempaa enemmän pakastintilaa valmiiden, lähetystä odottavien tuotteiden varastointiin, mikä helpottaa tuntuvasti tuotteiden puskurointia. Marja Bothnia Berriesin päätavoitteina pakkasvarastolleen olivat tehokas tilankäyttö sekä nopea pääsy jokaiselle kuormalavalle. SSI Schäfer täytti nämä vaatimukset toimittamalla asiakkaalle 32 käytävän laajuisen siirtohyllystön, joka on jaettu kolmeen erilliseen pakastinjärjestelmään. Laitteistoa täydentää Logisoft-varastonhallintajärjestelmä. Marja Bothnia Berriesin pakasteosastolla on nyt tilaa kaikkiaan 5 704 lavalle.

Projekti viimeisteltiin ja otettiin käyttöön lokakuussa 2021.

Yhteyshenkilö

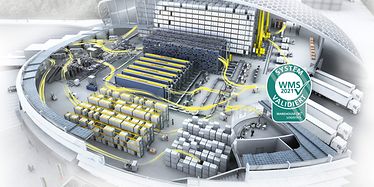

SSI SCHAEFER Software successfully validated again

The Fraunhofer Institute for Material Flow and Logistics (IML) has successfully validated SSI SCHAEFER software in the validation of Warehouse Management System (WMS) solutions. With the help of the manufacturer-independent "WMS Online Selection", Fraunhofer IML supports companies in selecting the optimal suitable WMS and provider. The validation signet once again confirms the quality of SSI SCHAEFER software solutions.

The platform warehouse-logistics.com, operated by Fraunhofer IML, has been one of the best-known portals for Warehouse Management Systems worldwide for more than 20 years. Since 2020, the original "WMS Database" has become a cross-system "Logistics IT Database" by adding further logistics IT systems. The functional comparison of more than 90 logistics IT systems, free market studies and publications as well as the full range of consulting services in the field of logistics IT make warehouse-logistics.com a holistic information platform about software for logistics.

WAMAS® WMS in the top field

In the run-up to the validation, the experts of "Warehouse Logistics" checked more than 3,700 requirement criteria. The success certifies that the standardized logistics software WAMAS, developed in-house by SSI SCHAEFER, has the highest breadth and depth of functionality as well as proven stability and performance as the cornerstone for seamlessly interlocking processes and highest throughputs in modern, efficiently organized warehouses. The results of the qualification round published in August 2021 can be found online at https://www.warehouse-logistics.com/57/3/11917/news.html.

"The provision of the validation signet and the presence in the logistics IT database of the portal is the confirmation of a renowned and globally recognized authority that our WMS solutions for modern warehouse management demonstrably meet the highest requirements," says Notker Steigerwald, Head of Business Unit Logistics Solutions at SSI SCHAEFER.

SSI SCHAEFER believes, after being recognized in the Gartner® Magic Quadrant™ for Warehouse Management Systems[1] by Gartner, Inc., in July 2021, the validation of WAMAS by the experts of "Warehouse Logistics" is once again an official seal of approval for SSI SCHAEFER's high-performance logistics software.

With more than 1,100 employees in the Software Solutions division, the SSI SCHAEFER Group with a total of 10,500 employees is a market partner that knows the requirements of modern material handling from hardware to software and translates them into sustainable solutions for its cross-industry customers.

[1] Gartner, Magic Quadrant for Warehouse Management Systems, Simon Tunstall, Dwight Klappich, 30 June 2021.

Gartner disclaimer:

Gartner does not endorse any vendor, product or service depicted in its research, and does not advise technology users to select only those vendors with high ratings or other attributes. Gartner publications reflect the views only of the Gartner research organization and should not be relied upon as factual. Gartner disclaims all warranties, express or implied, with respect to this research including fitness or suitability for a particular purpose.

GARTNER and MAGIC QUADRANT are registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally and are used herein with permission. All rights reserved.

Yhteyshenkilö

Ponsse panostaa tulevaisuuteen katsovaan varastoratkaisuun

Ponsse, yksi maailman johtavista metsäkonevalmistajista, onnistui kasvattamaan kokoonpanolaitoksensa tuotannon tehokkuutta 50 prosenttia. Yhtenä kasvun mahdollistajana toimii SSI Schäferin toteuttama tuotannon sisälogistiikan älykäs automaatiojärjestelmä.

”Aikaisempi varastoratkaisumme ei pystynyt enää varmistamaan sellaista kapasiteettia ja suorituskykyä, jota tarvitsemme vastataksemme kasvaneeseen kysyntään", Ponsse-konsernin logistiikkapäällikkö Tapio Honkanen kertoo. Sen vuoksi vuodesta 1995 asti pörssilistattu konepajayhtiö päätti automatisoida ja digitalisoida kokoonpanolinjan materiaalien sisälogistiikan ja rakentaa uuden logistiikkakeskuksen Pohjois-Savon Vieremässä sijaitsevalle tehtaalleen. Automatisoidun sisälogistiikan suunnittelu ja toteutus annettiin SSI Schäferin tehtäväksi. ”Nykyaikaiseen teknologiaan perustuva vakuuttava peruskonsepti, jolla voidaan toteuttaa tilaa säästävä varastointi, sekä tehokkaat, automatisoinnilla optimoidut keräilyprosessit", Honkanen listaa urakoitsijan valintaan johtaneita keskeisisiä seikkoja. ”SSI Schäfer ymmärsi vaatimuksemme, analysoi ongelmat, perehtyi lukuihin ja läpimenotarpeisiin – ja esitti sitten tulevaisuuteen katsovan konseptin, joka oli suunniteltu vastaamaan tarpeitamme. SSI Schäferin toteuttama ratkaisu auttoi meitä kasvattamaan tuotannon tehokkuutta 50 prosenttia. Sen lisäksi ratkaisu kasvatti merkittävästi varastotoimintojemme tuottavuutta ja laatua.”

Vuonna 1970 perustettu Ponsse on maailman johtavia metsäkonevalmistajia. Yhtiön tuotevalikoimaan sisältyy eri kokoluokkien metsäkoneita kaikkiin eri puolilla maailmaa vallitseviin ilmasto- ja maaperäolosuhteisiin. Ponsse suunnittelee ja valmistaa kaikki keskeiset komponentit yhtiön tehtaalla Vieremän kunnassa. Tehdasta on laajennettu viime vuosina alkuperäisestä 300 m2 pinta-alasta 4 ha pinta-alaan. Tuotanto saa tarvittavat komponentit ja materiaalit viivytyksettä tehtaaseen liitetystä uudesta keskitetystä logistiikkakeskuksesta. Siellä varastoidaan 8000 erilaista tuotetta alkaen 4000 kg painoisista koneakseleista pieniin elektroniikan komponentteihin asti. Kaksivuoroperiaatteella toimiva logistiikkakeskus toimittaa tehtaan tuotantolinjoilla sijaitseviin 100 eri noutopisteeseen valmiiksi koostettuja komponentteja ja kokoonpanosarjoja. Komponenttien varastointia ja sarjojen nopeaa, virheetöntä keräilyä sekä tuotantolinjojen kysyntävetoista palvelua varten SSI Schäfer toteutti automaatiokonseptin, joka käsittää kuormalavapohjaisen korkeahyllyvaraston, sukkulajärjestelmän pienosien varastointiin, kompaktin kuljetinjärjestelmän ja ergonomiset keräilyasemat.

Siirtyminen automaatioon ja digitaalisuuteen

Toimittajilta saapuu logistiikkakeskukseen joka päivä keskimäärin 12 rekallista metsäkoneiden komponentteja. Ponsse on integroinut logistiikkakeskukseen saapuvan tavaran vastaanottorampit, jotta tämä hyvin moninainen nimikevalikoima saadaan purettua tehokkaasti. ”Lastit pystytään purkamaan kätevästi sivusta haarukkatrukeilla”, SSI Schäferin Huoltopäällikkö Jani Eronen kertoo. Saapuva tavara siirretään vastaanoton ja tarkastuksen jälkeen logistiikkakeskukseen uudelleenpakkaukseen ja varastopaikkoihin. Molemmissa automatisoiduissa varastojärjestelmissä sisään- ja ulossyöttö tapahtuu varastojärjestelmien etuvyöhykkeelle asennetulla 200 metriä pitkällä lava- ja laatikkokuljetusjärjestelmällä.

Ponsselle saapuvat kuormalavat syötetään kuljetinjärjestelmään haarukkatrukeilla, mistä ne lähtevät korkeahyllyvarastoon. Lavakuljetusjärjestelmä siirtää lavat hyllystöhisseille. Kolmen käytävän automatisoidussa korkeahyllyvarastossa on 3700 varastopaikkaa ja SSI Schäferin SSI Exyz -hyllystöhissit varmistavat varastointi- ja noutoprosessien tehokkuuden yhdellätoista hyllytasolla. Jokainen hyllystöhissi yltää 40 kaksoissyklin tuntikapasiteettiin. Kun kokoonpanoasemilta tulee tilaus, lavat noudetaan neljään rinnakkaiseen keräilyasemaan korkeahyllyvaraston etuvyöhykkeellä. Siellä tarvittavat suuret komponentit keräillään manuaalisesti kuormalavoilta vaunuihin ja kuljetuslavoille. Tämä tapahtuu näytön opastamana ergonomisten nosturien avulla. Kuljetinjärjestelmä kuljettaa alkuperäiset kuormalavat takaisin Exyz-hyllystöhissin siirtoasemille varastoitaviksi. Tällä tavoin keräillään 1600 tilausriviä päivässä suuria ja raskaita komponentteja. Haarukkatrukit poimivat tuotantolinjoja varten lastatut kuljetuslavat ja – vaatimuksista riippuen – ne yhdistetään sukkulavarastosta keräiltyihin pienosiin.

Pienempien koneenosien täysin automatisoitua varastointia varten SSI Schäfer rakensi huippumodernin ja joustavan SSI Cuby -sukkulajärjestelmän. Standardoitu varastointijärjestelmä koostuu hyllystöistä, nostolaitteista, yhdestä Cuby-sukkulasta per varastotaso, sukkuloiden noston, kunnossapidon ja mahdolliset tasosiirrot mahdollistavasta sukkulanosturista sekä ohjausohjelmistosta. ”Modulaarisen suunnittelun ansiosta komponentit skaalautuvat hyvin, minkä vuoksi ratkaisu soveltuu ihanteellisesti pienosavaraston ensimmäiseksi automaatio- ja digitalisaatioratkaisuksi”, SSI Schäferin Eronen toteaa. ”Cuby-sukkulajärjestelmän kokonaiskonsepti tarjoaa siten älykkään ratkaisun tilankäytön optimointiin pienosavaraston sisälogistiikassa.” Esimerkiksi varastointialueen etuosaan integroitu, innovatiivinen ja skaalautuva, laatikot hyllytasoille syöttävä nostojärjestelmä varmistaa kompaktin tilankäytön ja maksimaalisen varastointikapasiteetin. Sukkulat hyödyntävät koko hyllystön syvyyttä varastoinnissa. Lastauslaitteen ohjaamiseen käytetty patentoitu hyllysyvyystuki on järjestelmäteknologialtaan ainutlaatuinen. SSI Schäfer Cuby-sukkulateknologia mahdollistaa siten jopa 35 kg muovi- ja pahvilaatikoiden varastoinnin ja varmistaa samalla erinomaisen käyttövarmuuden ja korkeat läpimenovolyymit.

Kierrossa 15 000 laatikkoa

Näin on myös Ponssen varastossa. Yksikäytäväisen, 65 m pitkän Cuby-järjestelmän 34 sukkulaa palvelevat noin 15 000 varastopaikkaa. Laatikot varastoidaan sinne yksittäiskeräilyä varten. Laatikot siirtyvät varastosta kuljetinjärjestelmään ja sukkulajärjestelmän esivyöhykkeen kahdelle keräilyasemalle kahden hissin avulla. Tehokas kaksoishissiratkaisu lastauslaitteen kaksikerrostoiminnolla varmistaa maksimaaliset läpimenovolyymit. Yli 50 prosenttia toimittajien toimittamista pienosista on pakattu valmiiksi varastoyksiköihin, jotka on tarkoin suunniteltu kokoonpanoasemien tarpeisiin. Tavaroiden vastaanoton jälkeen ne viedään uudelleenpakkausasemiin, missä ne yksinkertaisesti otetaan lavoilta tai laitetaan laatikoihin ja siirretään kuljettimella sukkulavarastoon. "Varastointi ja nouto sekä porrastus keräilyasemilla tapahtuvat sitten automaattisesti”, Ponssen logistiikkapäällikkö Honkanen kertoo. Pienosien keräily kokoonpanolinjojen tarpeisiin tapahtuu kahdessa laatikkokeräilytyyppisessä goods-to-person-työpisteessä. Ponssen varastossa kiertää noin 15 000 SSI Schäferin LTF6220-laatikkoa, ja niissä osat sekä varastoidaan varastopaikoilla että kuljetetaan tuotantolinjalle.

Nostinten ja sukkuloiden yhteispeliä koordinoidaan varaston etuvyöhykkeellä kuljettimen ja kahden goods-to-person-työpisteen kanssa, minkä ansiosta Cubyn esivyöhykkeellä Ponssen työntekijät pystyvät jopa 6000 poiminnan päivävauhtiin. Kuljettimet ja nostimet palauttavat vapautuvat laatikot Cuby-järjestelmään. Tilausrakenteesta riippuen Cuby-järjestelmästä tulevien komponenttien toimituslaatikot siirretään joko suoraan kokoonpanolinjoille tai yhdistelypisteille, missä ne yhdistetään korkeahyllyvarastosta lavoilla tuleviin komponentteihin. Lopuksi komponentit toimitetaan käyttöpisteelle haarukkatrukilla tai hinausvaunulla. Toimituslaatikot palautetaan tyhjennyksen jälkeen Cuby-järjestelmän toimituspuskuriin uutta täyttöä varten.

”Harmoninen projektitoimitus ja ensiluokkaiset teknologiaratkaisut materiaalivirtojen automatisointiin”, Ponssen logistiikkapäällikkö Honkanen summaa. ”Automatisoitu varastointijärjestelmä maksimoi käytettävissä olevan tilan kapasiteetin. Käyttövarmuus ja kapasiteetti ovat moninkertaistuneet. Automatisoidut ja optimoidut sisälogistiikkaprosessit ovat nopeuttaneet tuotantolinjojen ja kokoonpanoasemien komponenttisyöttöä ja kasvattaneet näin tehtaan tuotannon tehokkuutta yli 50 prosenttia. Voidaankin sanoa, että SSI Schäferin toteuttama konsepti on meille tulevaisuuteen katsova ratkaisu.”

Määränpäänä verkkokauppa: Tallink purjehtii kohti uusia mahdollisuuksia

Tallink on tehnyt kesäkuussa 2021 SSI SCHÄFERin kanssa sopimuksen seitsemän uuden SSI LOGIMAT® -varastoautomaatin toimituksesta.

Tallink on matkustajaliikenteen ja lyhyiden risteilyjen johtava tarjoaja Itämeren alueella. Yhtiön pääkonttori sijaitsee Viron Tallinnassa. Vuonna 2020 Tallink valittiin luotetuimmaksi Suomessa palvelujaan tarjoavaksi risteilylauttaliikennöijäksi. (Lähde: statista.com)

Pandemia toi Tallinkille merkittäviä haasteita, sillä kriisin murjomat merikuljetus ja risteilyt ovat yhtiön ydinliiketoimintaa. Vuonna 2020 Tallinkin matkustajamäärä laski edellisvuodesta 62 % ja rahtikuljetusten volyymi 5 %; vuonna 2019 matkustajia oli vielä 9,8 miljoonaa ja rahtiyksikköjä kuljetettiin yhteensä 380 000 kappaletta. Laivanvarustamo käynnisti useita erilaisia sopeutumishankkeita kesällä 2020. Näihin kuuluivat mm. kotimaan lyhyet risteilyt sekä satamassa pysyen toteutetut tapahtumat. Pandemia-ajan edestakaisin sahaavat rajoitukset aiheuttivat kuitenkin jatkuvaa epävarmuutta.

”Koronavirus on muuttanut asiakkaiden ostoskäyttäytymistä. Verkkokaupan kasvu on ollut vahvaa. Tiesimme, että meidän on uudelleenarvioitava Tallinkin logistiikkakeskuksen prosessit, jotta ne saadaan tukemaan sekä konsernin sisäisten B2B-asiakkaiden että kasvavan B2C-verkkokaupan tarpeita”, kertoo Tallink Duty Freen logistiikkajohtaja Marko Jurkatamm.

Verkkokauppatilaukset ovat yleisesti ottaen pienempiä, joten varustamo tunnisti tulevaisuuden keskeisiksi tarpeiksi varastokapasiteetin lisäämisen ja tarkemman keräilyn.

”Tallink on käyttänyt SSI LOGIMAT -automaattia jo yli viisi vuotta. Olemme olleet erittäin tyytyväisiä SSI SCHÄFERin palveluun ja yhteistyöhön. Oli siis helppo päätös jatkaa heidän kanssaan uudella sopimuksella. SSI Schäfer Finland hoiti analyysin ja suunnittelun mallikkaasti. Hyvä ratkaisu löytyi nopeasti yhteistyössä. Projektissa oli muutamia tarkennusta vaativia yksityiskohtia, mutta kokonaispalautteena työ tuli todella hyvin hoidettua”, Marko Jurkatamm kommentoi.

Seitsemän SSI LOGIMAT -lisämoduulin ansiosta Tallinkin ei tarvitse laajentaa olemassa olevaa fyysistä varastotilaa. Laitteisto auttaa myös parantamaan keräilyn tarkkuutta, mikä on tärkeää B2C-segmentissä. Tallink päätti ottaa kaiken hyödyn irti uudesta ratkaisusta kahden SSI LOGIMATin lisävarusteen avulla. LOGIDUAL nopeuttaa keräilyä siirtämällä keräilyalustoja kahdessa tasossa kullakin käyttöaukolla. LOGIPOINTER puolestaan osoittaa tarvittavien nimikkeiden tarkan sijainnin lasersäteen avulla. Yhdessä nämä lisävarusteet auttavat Tallinkia järjestelmällisempään, optimaalisempaan ja aiempaa virheettömämpään keräilyyn.

Tallinkin tähtäimessä on miljoonan tilausrivin keräily vuositasolla verkkokaupan puolella. Tällä hetkellä varustamo on tuon tavoitteen puolimatkassa.

Projekti luovutetaan tilaajalle helmikuussa 2022.

Yhteyshenkilö

The global 3PL company DSV opts for the overhead conveying system SSI Carrier

Flexible pouch sorter solution for e-commerce fulfillment

Changes in consumer and purchasing behavior are posing major challenges for many companies. Customers expect permanent availability of products and fast delivery to their doorstep. This increases the pressure on companies to more efficiently meet the ever more complex customer requirements. The need for automation with reliable technological and digital systems also rises, as orders need to be processed quickly to ensure a high level of service. Modern logistics systems such as the pouch sorter SSI Carrier by SSI SCHÄFER are able to meet these requirements. Thanks to this overhead conveying system, the global 3PL transport and logistics company DSV has sufficient capacity to deal with their customers’ exponential e-commerce growth and the massive seasonal order peaks - while handling products extremely gently.

Around the globe, numerous companies from different industries face similar challenges resulting from changed consumer and buying behavior, the turbulent market conditions and the consequences of the global pandemic. More and more consumers are enjoying anytime/anywhere availability and doing their shopping online. In order to remain competitive, retailers require high-performance intralogistics to support store deliveries and end customers’ direct orders from a single distribution center. Modern logistics solutions must be as compact, flexible and efficient as possible to ensure fast access to the required goods, deal with changing order profiles, master peak times efficiently and include immediate availability of returns.

The SSI Carrier meets all these complex requirements. The SSI SCHÄFER pouch sorter is a space-saving and versatile overhead conveying system for the parallel processing of different sales channels. One single load carrier enables the conveying, buffering, sorting and sequencing of flat and hanging goods in one system, while simultaneously achieving high throughput. The automated sorting solution brings customer orders to packing stations in the desired sequence regardless of the order size and ensures effective returns handling, which makes the solution particularly suitable for e-commerce. The SSI Carrier only requires a minimum footprint, ensures highest storage density and offers high scalability and flexible system extension by a modular, individually adaptable design.